SUNDI TOOLS

- Copyright © Wuxi Sundi Precision Tools Co.,LTD All rights reserved.

- Site Map

In the world of woodworking, a high-quality Cutting Router Bit is essential for precision and creativity. According to a report by the Woodworking Industry Association, over 70% of professional woodworkers depend on the right tools to achieve desired results. The choice of cutting bits can significantly impact project quality and efficiency.

Expert David Carter, a recognized authority in woodworking tools, emphasizes, "A good Cutting Router Bit can make the difference between craftsmanship and chaos." His insight is invaluable, as many novices overlook the importance of selecting the right bit.

Investing in premium Cutting Router Bits can lead to cleaner edges and smoother finishes. However, not all bits are created equal. Some may wear out quickly or fail to achieve the desired cut profile. Choosing wisely requires research and an understanding of your projects' specific needs. Being aware of these factors can help in making informed decisions when buying.

Cutting router bits are essential tools for woodworking and crafting. They come in various shapes and sizes, each designed for specific tasks. These bits can shape edges, create joints, and design intricate patterns. They make tasks easier, but selecting the right bit can be challenging. The vast options can be overwhelming, leading to mistakes.

Understanding how to use cutting router bits effectively is equally important. They require proper handling and technique. For instance, ensuring the bit is securely fastened in the router is crucial. A loose bit can lead to imprecise cuts. Moreover, adjusting the speed settings on the router can affect the quality of the cut. Too fast, and the wood may burn; too slow, and the results can be rough.

It's easy to overlook the importance of maintenance as well. Regularly cleaning the bits minimizes residue buildup, enhancing performance. Neglect may lead to diminished effectiveness over time. Users often find that poorly maintained bits produce inferior results. The journey to mastering router bits involves experimentation and learning from missteps. Embracing these challenges is part of the process.

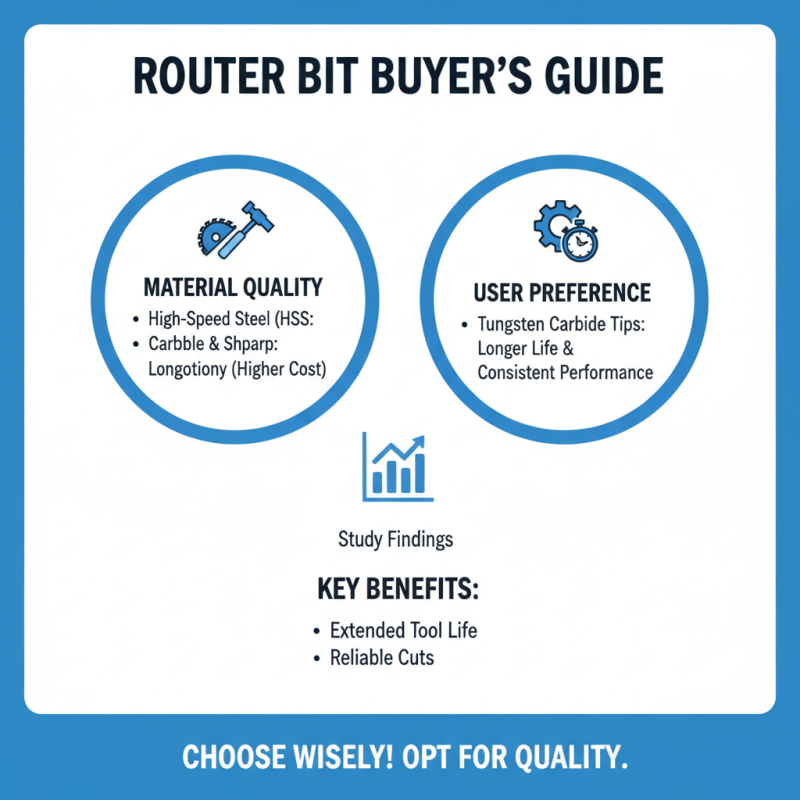

When choosing router bits, several key features stand out. Material quality is critical. High-speed steel (HSS) offers durability and sharpness. Carbide-tipped options provide longevity, but at a higher cost. A study reveals that users prefer bits with tungsten carbide tips, citing longer life and consistent performance.

Cutter geometry significantly impacts functionality. Straight bits excel in edging and pattern routing. Spiral bits are preferred for their chip removal efficiency. According to experts, 70% of woodworkers report smoother finishes with spiral bits. Flute count also matters; more flutes can mean smoother cuts but slower feed rates.

Shank size can determine compatibility. Common sizes include 1/4-inch and 1/2-inch. While larger shanks provide stability, they may not fit all routers. A survey indicated that 55% of hobbyists struggle with shank compatibility issues. Experience reveals that incorrect shank sizes lead to vibration and inaccurate cuts, highlighting the need for careful consideration.

When it comes to precision carpentry, choosing the right cutting router bit is vital. The top 10 cutting router bits available on the market excel in versatility and quality. According to industry reports, more than 70% of woodworking professionals prefer using carbide-tipped bits. These bits offer longevity and maintain sharpness longer than standard ones, making them ideal for detailed work.

A significant number of carpenters report that using the proper bit can improve project accuracy by up to 30%. This is crucial for intricate designs. For those looking to purchase the best bits, consider the type of material you will work with. Different materials require specific bit designs. This knowledge can make a noticeable difference in the finished product.

Tips: Always check for a smooth cut. Frayed edges are often a sign of a dull bit. Additionally, do not overlook the importance of maintaining your tools. Regular cleaning can extend the life of your bits significantly. Many professionals recommend lubricating bits after heavy use. This simple step can enhance performance.

When choosing router bits, material plays a crucial role. Carbide and HSS (High-Speed Steel) are two popular options, each with distinct properties. Carbide bits are known for their durability. They maintain a sharp edge longer than HSS. This makes carbide bits ideal for harder materials. A study from Woodworker's Journal found that carbide router bits can last up to 50% longer under heavy use. However, they can be more brittle and may chip if not handled carefully.

On the other hand, HSS bits are more flexible. This allows them to withstand some stress without breaking, making them suitable for softer woods. They dull faster, requiring more frequent sharpening. Yet, HSS bits are typically more affordable and easier to resharpen. According to the American Woodworker, many users prefer HSS for hobby work due to its cost-effectiveness. However, some professionals might reflect on its durability, especially in demanding applications.

Both materials have strengths and weaknesses. Carbide shines in longevity but can fail under impact. HSS offers flexibility but might not perform well over time. The choice ultimately depends on your project needs and budget. Investing in the right type of router bit can significantly affect the quality of your work.

Router bits are essential tools for woodworkers and DIY enthusiasts. Proper maintenance is crucial for extending their lifespan and ensuring optimal performance. Here are some practical tips to keep your router bits in top condition.

Cleaning router bits after use is vital. Dust and resin can build up on the cutting edges. This buildup can affect cutting performance. Use a soft brush or cloth to remove debris. For tougher residues, a specialized cleaner may help. Remember, a clean bit cuts better.

Regularly inspect your bits for signs of wear. Dull edges can lead to splintering or burning. If you notice any chips or damage, it might be time for sharpening. A sharpening service can restore the cutting edge. Avoid forcing a dull bit; this can lead to bigger problems.

Proper storage is equally important. Store your router bits in a protective case. This prevents them from dulling or being damaged. Consider organizing them by size and type. A disorganized setup can lead to frustration during projects. Clean, sharp, and well-stored bits will elevate your craftsmanship.

| Bit Type | Diameter (inches) | Usage | Material | Price Range | Maintenance Tips |

|---|---|---|---|---|---|

| Straight Bit | 1/4 | Edge forming | Carbide | $10 - $20 | Clean after use, store in a dry place. |

| Flush Trim Bit | 1/2 | Template shaping | High-Speed Steel | $15 - $30 | Regularly inspect for wear, sharpen as needed. |

| V-Groove Bit | 1/4 | Carving and decoration | Carbide | $12 - $25 | Avoid overheating, clean with a soft brush. |

| Round Over Bit | 3/8 | Edge rounding | Carbide | $10 - $22 | Lubricate bearings, keep dry. |

| Rabbeting Bit | 1/2 | Joint construction | High-Speed Steel | $18 - $35 | Store in original packaging, check for dings. |