SUNDI TOOLS

- Copyright © Wuxi Sundi Precision Tools Co.,LTD All rights reserved.

- Site Map

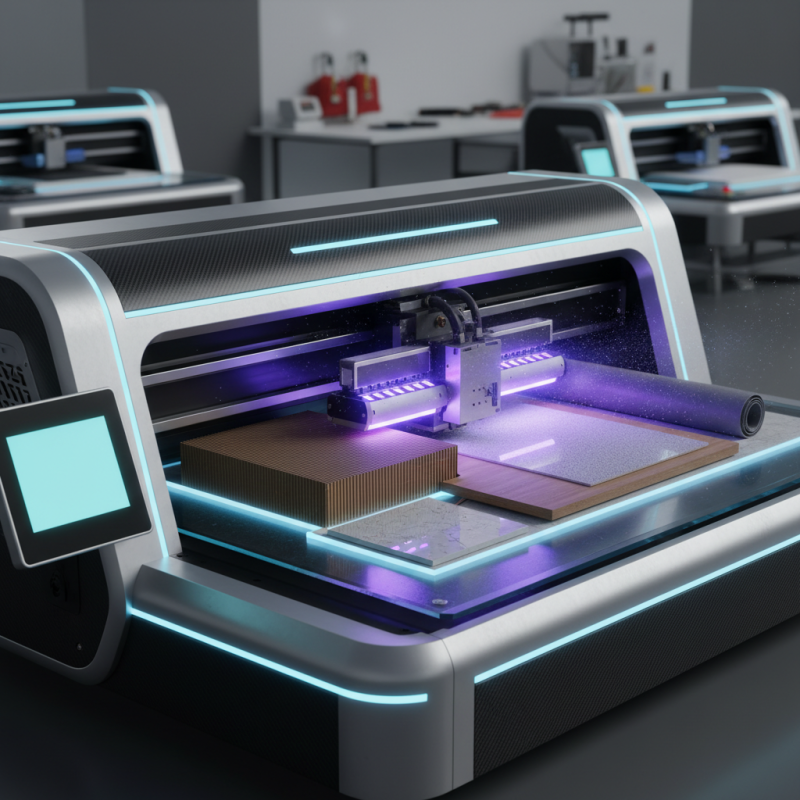

In the ever-evolving landscape of digital printing, the "Flatbed UV Led Printer" stands out as a transformative technology. According to the latest report by MarketsandMarkets, the UV printer market is projected to reach USD 5.8 billion by 2026, highlighting strong growth post-pandemic. This significant progression is spurred by the increasing demand for customizable printing across various sectors, from signage to packaging.

Dr. Emily Carter, an industry expert from the Digital Printing Association, notes, "The versatility and efficiency of Flatbed UV Led Printers have set a new standard." This technology enables high-quality prints on diverse materials, leading to unique solutions in advertising and decor. Additionally, it is known for its eco-friendly features, minimizing volatile organic compounds (VOCs).

However, challenges remain in terms of understanding the full capabilities of this technology. Many businesses still underutilize their printers due to a lack of training and knowledge. Enhancing user education could unlock greater potential in the Flatbed UV Led Printer market. Ultimately, while the prospects are promising, the industry must focus on bridging gaps to maximize these innovative tools.

The history of flatbed UV LED printers reflects an impressive evolution. In the early 2000s, the technology emerged as a response to the need for high-quality printing on various surfaces. These printers utilize UV light to cure inks instantly. This innovation quickly gained attention in industries like signage and packaging.

By 2010, flatbed UV LED printers became more accessible. Data from industry reports showed a 30% growth in their adoption within five years. The demand was driven by their versatility and efficiency. These printers could handle materials like wood, glass, and metal. However, challenges remained. Initial costs were often prohibitive for small businesses. Many shops struggled with the learning curve associated with new technologies.

Today, flatbed UV LED printers are more refined. Features like increased speed and better ink formulations have emerged. A recent study revealed that 45% of companies now prioritize eco-friendly solutions. However, not all printers deliver optimal results on every substrate. This inconsistency sometimes leads to customer dissatisfaction. Brands still face the challenge of balancing price with performance. Overall, while the technology has significantly evolved, continuous improvement is essential for future growth.

| Feature | Description | Benefit |

|---|---|---|

| UV LED Technology | Uses ultraviolet light to cure ink as it is printed. | Faster drying times and reduced energy consumption. |

| Versatility | Can print on a variety of surfaces including wood, glass, metal, and plastic. | Expands possibilities for different applications and markets. |

| High Resolution | Offers resolutions up to 1200 dpi. | Provides sharp and vibrant prints for high-quality results. |

| Eco-Friendly Inks | Utilizes eco-friendly and low-VOC inks. | Reduces environmental impact and meets regulatory standards. |

| User-Friendly Software | Compatible with various design software. | Eases the design process and allows for quick adjustments. |

| Automated Functions | Includes features like auto-alignment and media sensing. | Increases efficiency and reduces the chance of errors. |

When considering the features of the best flatbed UV LED printers of 2026, it’s essential to look at both performance and versatility. These printers often excel in achieving vibrant, detailed prints on various materials. The ability to print on products ranging from wood to acrylic opens new creative possibilities. Users frequently highlight the high-quality output, especially for detailed graphics and color fidelity.

Another key feature is the speed of operation. Many models offer quick print speeds, allowing for efficient production. This is beneficial for businesses that require high-volume prints. However, some users may notice variations in speed based on the complexity of the print job. This inconsistency can be frustrating, especially when meeting tight deadlines.

User-friendly interfaces are also common in top models. An intuitive control panel can reduce the learning curve for new operators. Nevertheless, some features can feel overwhelming. This complexity can lead to user errors or underutilization of the printer's capabilities. It's vital that users take the time to fully understand all functionalities to maximize printer performance.

Flatbed UV LED printers are revolutionizing the way we print on various materials. They excel in versatility, allowing printing on surfaces such as glass, wood, metal, and plastic. This adaptability opens new doors for creative projects and business applications. The ability to print directly on these materials enhances efficiency by eliminating the need for extra steps, like applying transfer stickers. It saves time, reducing production costs.

One key advantage of using these printers is their eco-friendly nature. UV LED inks cure quickly, reducing the release of volatile organic compounds (VOCs). This makes the printing process safer for operators and the environment. However, some users might find the initial setup and calibration challenging. It can take time to master the settings for different materials, which may lead to some frustrations at first.

Moreover, the print quality is exceptional, offering vibrant colors and crisp details. Users can achieve intricate designs that stand out. Yet, achieving consistency in quality requires practice and careful monitoring. It's beneficial to invest time in understanding the printer's capabilities. Ultimately, the potential for unique applications and high-quality results makes flatbed UV LED printers a worthwhile consideration.

In 2026, the flatbed UV LED printer market is witnessing significant advancements. Data suggests a rise in demand by 15% annually. This growth indicates a keen interest in more efficient printing solutions across various industries. The competitive landscape is heating up, with numerous brands pushing the boundaries of technology.

For example, top models now feature enhanced color accuracy and faster printing speeds. They cater to diverse materials, from wood to glass. Leading reports highlight that printers with higher resolution capabilities are preferred, providing exceptional detail in printed images. Surprisingly, not all brands consistently deliver on durability. Some models struggle under heavy use, requiring frequent maintenance. This inconsistency raises concerns for businesses relying on these machines for high volume production.

Moreover, energy efficiency has become a focal point. Many consumers prioritize printers that consume less power. It's an essential factor, yet many machines still fall short. Users often report dissatisfaction with ink usage as well. Printers that promise cost-effective solutions may sometimes lead to hidden expenses. Balancing quality, efficiency, and cost remains an ongoing challenge for many buyers.

Flatbed UV LED printing technology is evolving rapidly. This evolution brings exciting changes to various industries. One notable trend is the push for sustainability. Manufacturers are focusing on eco-friendly inks. These inks reduce harmful emissions. Users are more aware of their environmental impact. This consciousness is shaping new features in flatbed printers.

Another significant trend is increased versatility. Modern flatbed printers can handle various materials. They can print on glass, wood, metal, and more. This flexibility opens new creative possibilities. Users are experimenting with textures and finishes that were previously unavailable. However, the technology is not without challenges. Adjusting print settings for different materials can be tricky. More training may be needed for users to optimize their prints effectively.

Cost efficiency is also a rising concern. Businesses seek printers that offer lower operational costs. Innovations aim to maximize output while minimizing resources. However, investing in advanced technology can be daunting. Some may hesitate, fearing the learning curve. The push for smart, connected devices complicates this further. Users may find themselves overwhelmed by numerous features. Balancing cutting-edge technology with practical usability remains crucial for future development.