SUNDI TOOLS

- Copyright © Wuxi Sundi Precision Tools Co.,LTD All rights reserved.

- Site Map

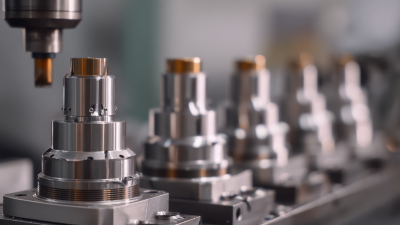

In the rapidly evolving landscape of modern manufacturing, the adoption of advanced tools and technologies has become imperative for optimizing production efficiency and reducing costs. Among these innovations, Carbide Drill technology stands out for its unparalleled ability to enhance machining performance and durability.

According to a report by Grand View Research, the global carbide tools market size is projected to reach USD 23.41 billion by 2027, driven by the increasing demand for precision-engineered products across various industries. Carbide drills, known for their superior hardness and heat resistance, significantly outperform traditional high-speed steel drills, achieving longer tool life and higher cutting speeds. As manufacturers strive to meet the challenges of precision and productivity, understanding the myriad benefits of Carbide Drill technology becomes essential for sustaining competitive advantage and driving industry growth.

Carbide drill technology has emerged as a game-changer in modern manufacturing, particularly in enhancing productivity. The advanced substrate and coating technologies in carbide drills allow for superior performance in machining challenging materials, such as aluminum alloys and hard metals. With innovations like three-flute designs and combination tools, the overall drilling efficiency has significantly increased. These developments not only extend tool life but also reduce tool wear, which is essential for maintaining consistent quality and reducing downtime in production settings.

Moreover, new drilling systems are taking advantage of enhanced lubricating and cooling techniques, which have shown to improve the machinability and surface integrity of components. Techniques such as minimum quantity lubrication (MQL) and advanced cooling methods help in maintaining the optimal temperature during operations, thereby preserving the integrity of the material being machined. The introduction of solid carbide drills equipped with specialized coatings further maximizes productivity, reflecting a growing trend towards more efficient and sustainable manufacturing processes. The adoption of these technological advancements is pivotal for manufacturers aiming to stay competitive in a fast-paced industrial landscape.

Carbide drill technology has revolutionized modern manufacturing, providing not just superior performance but also significant cost-efficiency. With their exceptional hardness and heat resistance, carbide drills maintain sharpness for longer periods compared to their high-speed steel counterparts. This reduced wear translates into fewer tool changes and less downtime, ultimately resulting in long-term savings on both materials and labor costs.

Tip: To maximize the lifespan of your carbide drills, ensure proper cooling during operation. Utilizing the correct cutting fluids can help reduce friction and keep the drill at optimal temperatures, further extending tool life.

Furthermore, investing in carbide drills can enhance the overall quality of your production. The precision they provide minimizes the need for secondary operations, allowing manufacturers to streamline processes and increase output. This efficiency not only reduces costs but can also improve customer satisfaction through consistent, high-quality products.

Tip: Regularly inspect and maintain your drills to ensure they are operating within the manufacturer's recommended specifications. Routine maintenance can prevent unexpected failures and extend the life of your tools, leading to even greater savings over time.

Carbide drill technology has revolutionized the manufacturing landscape, particularly in achieving precision and accuracy. These high-performance tools are crafted from tungsten carbide, a material renowned for its exceptional hardness and durability. This inherent strength allows carbide drills to maintain their cutting edges much longer than their high-speed steel counterparts, leading to consistent precision in drilling tasks. The stability offered by carbide drills minimizes the variance in hole sizes and shapes, which is crucial in industries where tight tolerances are mandatory.

Moreover, the ability of carbide drills to operate at higher speeds and feed rates significantly enhances productivity. With reduced tool wear, manufacturers can achieve more drill cycles within shorter time frames, ensuring that accuracy is not sacrificed for efficiency. This synergy of speed and precision makes carbide drills indispensable in modern applications, from aerospace to medical device manufacturing. By investing in carbide drill technology, businesses are not only improving their operational efficacy but also setting new standards for quality in their products.

| Feature | Description | Benefits |

|---|---|---|

| Material Composition | Carbide drills are made from tungsten carbide, which provides superior hardness. | Enhanced durability and longer tool life. |

| Cutting Precision | Designed for high accuracy in machining processes. | Improved part quality and reduced scrap rates. |

| Heat Resistance | Excellent thermal stability even at high cutting speeds. | Consistent performance over prolonged operations. |

| Versatility | Can be used on various materials including metals and composites. | Wide application range in multiple industries. |

| Cost Efficiency | Despite higher initial costs, they provide lower total cost of ownership. | Reduced downtime and increased productivity. |

Carbide drill technology has revolutionized modern manufacturing, particularly due to its exceptional durability and longevity. Unlike conventional drill options, carbide drills maintain sharpness and resist wear over time, making them a superior choice for high-volume production environments. This remarkable toughness not only enhances the precision of holes drilled but also significantly reduces the frequency of tool changes, leading to increased productivity and minimized downtime.

Carbide drill technology has revolutionized modern manufacturing, particularly due to its exceptional durability and longevity. Unlike conventional drill options, carbide drills maintain sharpness and resist wear over time, making them a superior choice for high-volume production environments. This remarkable toughness not only enhances the precision of holes drilled but also significantly reduces the frequency of tool changes, leading to increased productivity and minimized downtime.

To maximize the advantages of carbide drills, consider the following tips:

Carbide drill technology is revolutionizing modern manufacturing by enhancing material versatility and expanding operational capabilities. Unlike traditional drill bits, carbide drills provide superior durability and precision, allowing for efficient drilling through a wide array of materials, including wood, metal, and masonry. Recent industry reports indicate that the adoption of carbide drills can lead to a productivity increase of up to 40%, making them an invaluable asset for both DIY enthusiasts and professionals alike.

To maximize the advantages of carbide drill technology, consider the following tips: First, always match the drill bit to the material being worked on; this ensures optimal performance and longevity of the tool. Second, when drilling into harder materials, adjust the speed settings of your drill machine to prevent overheating and wear. Finally, taking the time to maintain your tools, such as regularly cleaning and lubricating your drill bits, can extend their life significantly and maintain their cutting efficiency.

As manufacturers continue to seek innovative solutions, the versatility of carbide drills sets the stage for expanded capabilities in various industries, from construction to manufacturing. By leveraging this technology, companies can better meet the diverse demands of their operations and enhance overall productivity.

This chart illustrates the percentage of material versatility improvements across various industries utilizing carbide drill technology. The data highlights how carbide drills enhance the capability to work with different materials, affecting manufacturing processes positively.