SUNDI TOOLS

- Copyright © Wuxi Sundi Precision Tools Co.,LTD All rights reserved.

- Site Map

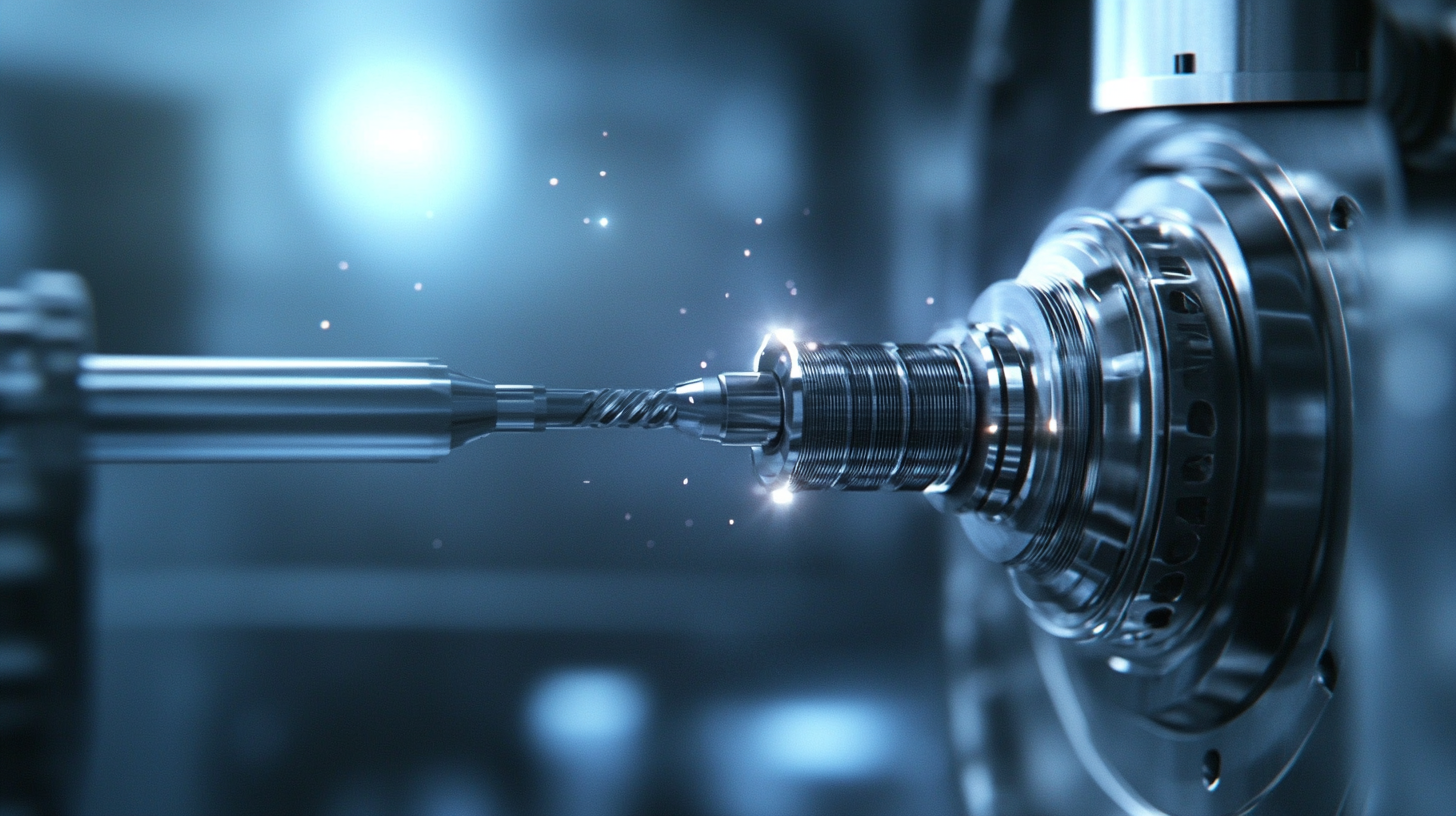

In the realm of precision engineering, achieving impeccable results is paramount, and one of the essential tools that facilitate this level of accuracy is the Hole Reamer. This specialized cutting tool is designed to refine existing holes to precise dimensions and finishes, ensuring that every component meets stringent industry standards. By employing the best Hole Reamer, engineers can not only enhance the precision of their work but also improve the efficiency of the manufacturing process.

This blog will delve into the various advantages of utilizing high-quality Hole Reamers in precision engineering, highlighting their role in achieving superior tolerances, surface finishes, and overall product reliability, which are crucial for maintaining a competitive edge in a constantly evolving industry.

Through an exploration of the different types and applications of Hole Reamers, we aim to provide insights that will help professionals make informed choices that elevate their engineering projects to new heights.

When it comes to precision engineering, choosing the right type of hole reamer is essential for achieving the desired accuracy and surface finish. Hole reamers can be categorized into various types, each designed for specific applications. The three primary types include straight reamers, taper reamers, and chucking reamers. According to a recent industry report from Precision Engineering Journal, the use of precision tools like reamers can improve hole tolerances by up to 50%, which is critical in industries such as aerospace and automotive manufacturing.

Straight reamers are ideal for enlarging existing holes to achieve a high level of precision with low cutting resistance. In contrast, taper reamers excel in creating angled openings, making them crucial in situations where a specific fit is required. Chucking reamers offer versatility and can fit into standard drill chucks, making them suitable for various applications. A study published by the International Journal of Manufacturing Science indicates that using the correct hole reamer type can increase efficiency by up to 30%, showcasing both time and cost savings.

**Tips:** When selecting a hole reamer, consider the material you are working with. Carbide reamers tend to last longer and provide better finishes for hard materials. Additionally, regularly maintaining and sharpening your reamers can extend their lifespan and improve performance. Always ensure that the reamer size matches the hole diameter for optimal results.

This chart illustrates the advantages of using the best hole reamer for precision engineering. The dataset reflects the scores of various benefits associated with hole reamers, highlighting their significance in enhancing precision, production speed, surface finish, tool longevity, and versatility.

In precision engineering, the choice of tools significantly impacts the quality of the final product.

High-quality reamers, particularly hole reamers, offer several advantages that are crucial for achieving tight tolerances and superior finishes.

According to a report by the Precision Engineering Society, using premium-grade reamers can improve hole accuracy by up to 30% compared to standard options, ensuring that components fit together seamlessly in complex assemblies.

One of the key benefits of utilizing high-quality reamers is their ability to maintain durability and sharpness over extended use.

Premium reamers are often constructed from advanced materials such as carbide or high-speed steel, which not only resist wear but also reduce the friction during operation.

This quality translates to longer tool life, with industry studies indicating that using top-tier reaming tools can extend service life by up to 50%, decreasing downtime and operational costs.

Furthermore, these reamers provide consistent results in various materials, from metals to plastics, ensuring versatility in a wide range of engineering applications.

When selecting a hole reamer for precision engineering, several factors must be considered to ensure optimal performance and high-quality outcomes. One of the key considerations is the material of the reamer. High-speed steel (HSS) and carbide-tipped reamers are commonly used due to their durability and ability to maintain sharp edges over extended use. A report from the Precision Tool Institute indicates that tools made from HSS offer a balance of cost-effectiveness and performance longevity, making them suitable for various engineering applications.

Additionally, the size and type of the hole being reamed are critical in selecting the appropriate reamer. Factors such as the diameter, depth, and tolerance requirements should influence the choice of a specific reamer type. For deeper holes, an expansion reamer may be preferred to accommodate adjustments in dimensions, while a straight fluted reamer works best for shallow holes. By carefully analyzing these factors, engineers can achieve the necessary precision in mechanical components, a requirement highlighted in recent industry analyses showing that precision engineering reduces defective parts by up to 30%. The right choice of hole reamer can significantly impact production efficiency and the quality of finished products.

To ensure the longevity and performance of your precision engineering projects, proper maintenance of your reamers is essential. Regularly cleaning your hole reamer after each use removes any built-up debris or chips that could affect its performance. You can achieve this by using a soft brush or compressed air to clear any obstructive material, which keeps the cutting edges sharp and effective for future tasks. Additionally, inspecting the reamer for signs of wear and tear allows for timely repairs or replacements, ensuring that the tools are always in optimal working condition.

To ensure the longevity and performance of your precision engineering projects, proper maintenance of your reamers is essential. Regularly cleaning your hole reamer after each use removes any built-up debris or chips that could affect its performance. You can achieve this by using a soft brush or compressed air to clear any obstructive material, which keeps the cutting edges sharp and effective for future tasks. Additionally, inspecting the reamer for signs of wear and tear allows for timely repairs or replacements, ensuring that the tools are always in optimal working condition.

Another key aspect of reamer maintenance is proper storage. Storing reamers in a designated toolbox or organizer minimizes the risk of damage. It's best to keep them in protective cases that prevent contact with other tools, which can cause nicks or dulling of the cutting edges. Furthermore, applying a light coat of machine oil before storage can prevent rust and corrosion, allowing precision engineers to maintain the tool's integrity for longer. These maintenance practices are vital not only for extending the life of your hole reamer but also for sustaining the overall quality of your precision engineering work.

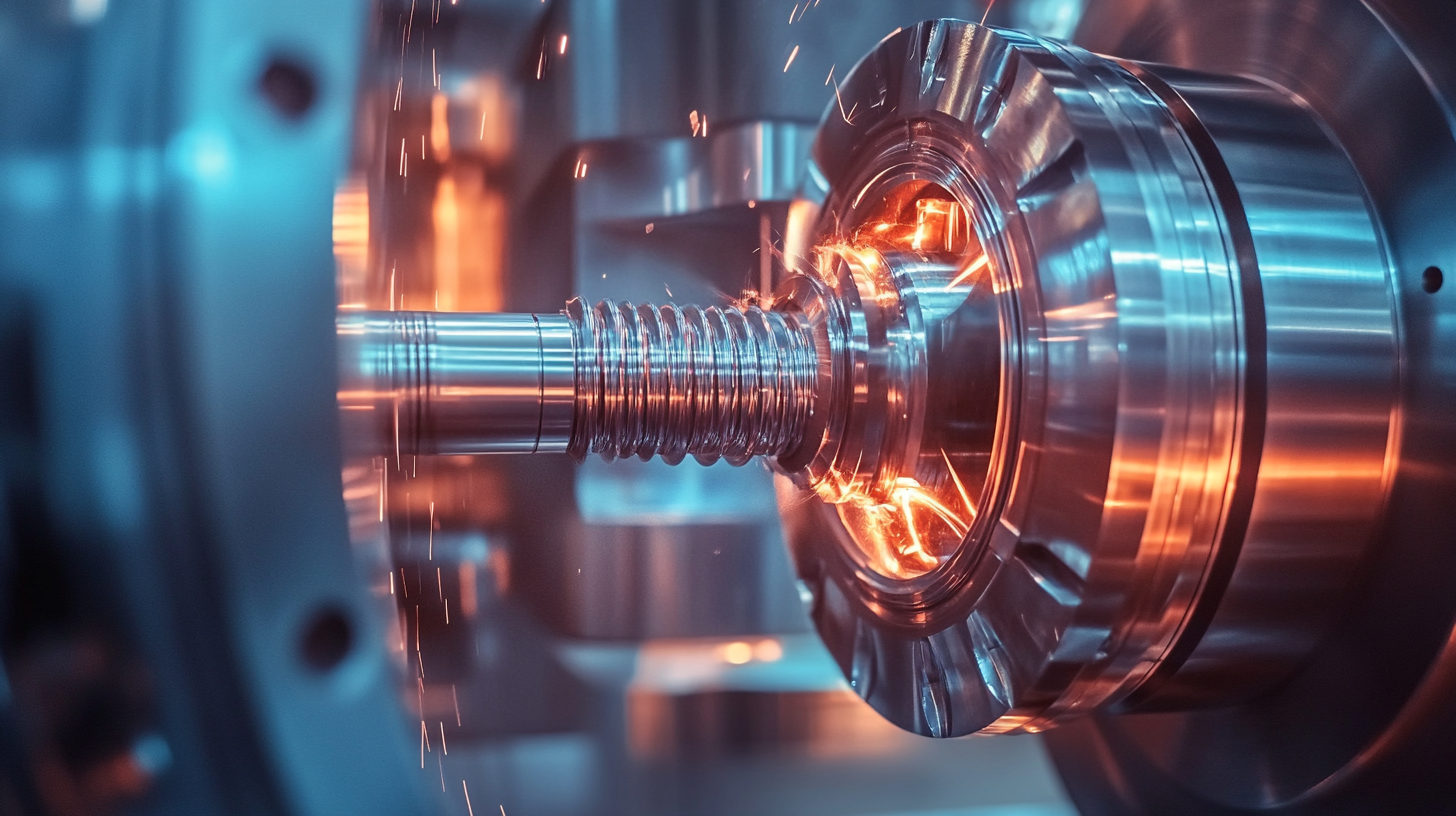

In the realm of precision engineering, hole reaming techniques have found indispensable applications across various industries. The ability to create precise, uniformly sized holes is crucial in manufacturing high-quality components, particularly in the aerospace and automotive sectors. Advanced hole reamers, designed for accuracy and efficiency, enhance the overall integrity and performance of engineered parts. With the integration of technology, precision hole reaming has become even more refined, allowing for tighter tolerances and better surface finishes.

Real-world applications of precision hole reaming are further bolstered by modern advancements in predictive technologies. For instance, recent developments in machine learning are transforming operations in the oil and gas sector. By utilizing comprehensive datasets, predictive models can now forecast the rate of penetration (ROP) in directional drilling, optimizing performance while reducing costs. This synergy between precision engineering and technological innovations highlights the essential role of specialized tools like high-quality hole reamers in streamlining production processes and improving outcomes in complex engineering projects.

| Application Area | Reaming Method | Material Type | Precision Level (μm) | Production Rate (units/hour) |

|---|---|---|---|---|

| Aerospace Components | Holes with Tapered Ends | Aluminum Alloys | 5 | 50 |

| Automotive Industry | Through Holes | Steel | 10 | 70 |

| Medical Devices | Blind Holes | Titanium | 8 | 30 |

| Civil Engineering | Large Diameter Holes | Concrete | 25 | 20 |

| Electronics | Micro-Holes | Copper | 3 | 100 |