SUNDI TOOLS

- Copyright © Wuxi Sundi Precision Tools Co.,LTD All rights reserved.

- Site Map

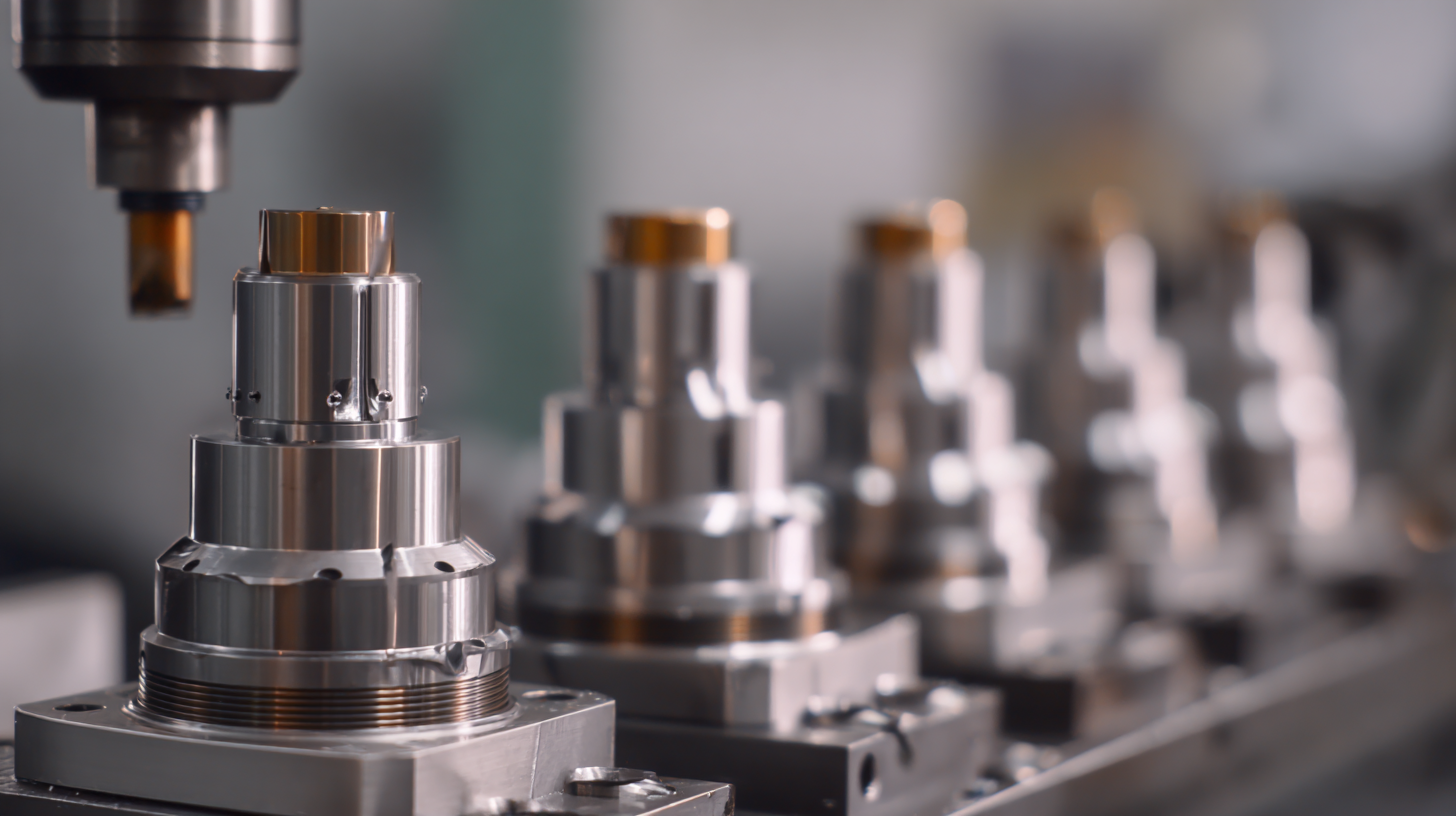

In the ever-evolving landscape of manufacturing, the selection of the right Milling Tools can significantly impact production efficiency and product quality. According to a report by Technavio, the global milling tools market is expected to grow by USD 1.91 billion from 2020 to 2024, driven by advancements in machine tooling technology and increasing demand for precision-engineered components. As manufacturers strive to enhance their operational performance, leveraging state-of-the-art milling tools becomes essential. These tools not only optimize machining processes but also reduce waste and improve turnaround times. In this guide, we will explore the myriad advantages of using the best milling tools for your manufacturing needs, equipping you with insights to make informed decisions that can elevate your production capabilities.

When it comes to precision manufacturing, the significance of selecting high-quality milling tools cannot be overstated. According to a report by the National Institute of Standards and Technology (NIST), manufacturers that invest in premium milling tools experience an average reduction in production errors by 30%. This reduction not only enhances product accuracy but also improves overall efficiency, leading to increased profitability. High-quality tools ensure tighter tolerances, which is crucial in industries such as aerospace and medical devices where precision is paramount.

Furthermore, a study by the American Machinist highlights that using superior milling tools can extend tool life by up to 50%. Longer-lasting tools mean less frequent replacements, reducing material waste and overall operational costs. The report underscores that the initial investment in high-quality milling tools often pays off through improved performance and lower maintenance expenses. As manufacturers continue to strive for excellence in their processes, the choice of milling tools will remain a critical factor in achieving success in competitive markets.

When it comes to selecting milling tools for your production line, several key factors can significantly influence the overall efficiency and quality of your manufacturing process. First and foremost, consider the material compatibility of the tools. Different materials, such as aluminum, steel, or composites, require specific types of milling tools to achieve optimal performance. Understanding the material composition will help in choosing tools that offer better durability and longer life, ultimately reducing maintenance costs.

Another important factor is the tool geometry. The design and shape of the milling tool can affect cutting performance, including factors such as chip removal and surface finish. Taking the time to evaluate different geometries based on your specific application can lead to enhanced precision and reduced cycle times. Additionally, the right tool coatings should not be overlooked, as they can provide increased resistance to wear and thermal degradation, further improving tool life and productivity on the production line.

This bar chart represents the key advantages of selecting high-quality milling tools for your production line. Each advantage is assessed based on its importance rating in a manufacturing setting.

When it comes to milling tools used in manufacturing, understanding the various types and their unique benefits is essential for optimizing production processes. From end mills to face mills, each type of milling tool serves specific purposes that can greatly enhance efficiency and precision in crafting complex components. For instance, end mills are versatile tools capable of performing a variety of operations, including slotting, contouring, and drilling, making them a staple in any machining operation.

When it comes to milling tools used in manufacturing, understanding the various types and their unique benefits is essential for optimizing production processes. From end mills to face mills, each type of milling tool serves specific purposes that can greatly enhance efficiency and precision in crafting complex components. For instance, end mills are versatile tools capable of performing a variety of operations, including slotting, contouring, and drilling, making them a staple in any machining operation.

Moreover, the advancements in technology, akin to those seen in the garment industry with automation and AI, have revolutionized milling tools as well. High-speed machining techniques and advanced materials have enabled manufacturers to achieve finer tolerances and improved surface finishes. This not only enhances product quality but also reduces cycle times, leading to significant cost savings. As manufacturers continue to explore and integrate the latest milling technologies, understanding the distinct advantages of each tool becomes pivotal in leveraging their full potential for enhanced productivity and competitive edge in the market.

Advanced milling tools play a crucial role in enhancing manufacturing efficiency and reducing waste. Manufacturers who adopt cutting-edge milling technologies can expect significant improvements in their operational processes. A recent comprehensive study on lean manufacturing concepts illustrates that integrating these principles can refine industrial processes by up to 30%, effectively minimizing waste and driving down production costs. The integration of advanced milling tools within these lean frameworks enables businesses to achieve a consistent and precise output, fostering a culture of continuous improvement.

Leveraging advanced milling tools not only streamlines production but also contributes to sustainability efforts by promoting the use of recyclable materials. With the push towards a circular economy, manufacturers are focusing on designing products that can be easily reused or repurposed. For instance, companies utilizing automated milling systems can implement more effective closed-loop processes, resulting in a 20% reduction in material waste, as reported in industry analyses.

Tips for manufacturers looking to upgrade their milling tools include investing in training for staff to handle new technologies effectively, which can enhance performance and reduce downtime. Additionally, regular maintenance of milling equipment is essential to ensure optimal operation and longevity, contributing to overall efficiency. Embracing these strategies will not only amplify productivity but also align manufacturing practices with sustainable goals.

The manufacturing industry is rapidly evolving, with an increasing demand for cutting-edge milling technology and tools. As industries strive for higher efficiency and precision, the need for advanced milling solutions has become paramount. Manufacturers are recognizing that utilizing the best milling tools not only enhances productivity but also significantly reduces operational costs. This trend is primarily driven by innovations in material science and engineering, enabling the production of high-performance tools that can withstand extreme conditions and deliver exceptional results.

In recent years, advancements such as computer numerical control (CNC) machining have revolutionized milling processes, allowing for greater automation and precision. These technologies permit manufacturers to execute complex designs with unparalleled accuracy, meeting the stringent requirements of modern production standards. Consequently, investing in state-of-the-art milling tools has transitioned from a luxury to a necessity for companies looking to maintain a competitive edge in the market. As the demand for customized products grows, adaptive milling technologies are proving essential for fulfilling the dynamic needs of customers while ensuring product quality and consistency.

| Tool Type | Material | Cutting Speed (m/min) | Flute Number | Coating Type | Application |

|---|---|---|---|---|---|

| End Mill | High-Speed Steel | 150 | 4 | TiN | General Milling |

| Face Mill | Carbide | 200 | 6 | TiALN | Heavy Cutting |

| Ball Nose End Mill | Cobalt | 120 | 2 | Diamond | Contoured Surfaces |

| Tapered End Mill | Aluminum | 180 | 3 | TiCN | Angle Milling |