SUNDI TOOLS

- Copyright © Wuxi Sundi Precision Tools Co.,LTD All rights reserved.

- Site Map

Choosing the right Plastic Injection Mold is crucial for any manufacturing project. Expert John Smith, an authority in the molding industry, once said, “The right mold can make or break a project.” This statement highlights the importance of selecting a suitable mold to achieve desired outcomes.

When deciding on a Plastic Injection Mold, consider your specific project requirements. Factors like material type, production volume, and complexity play significant roles in the decision-making process. A mold that works for one application may fail in another. It's also wise to evaluate the costs involved. Higher-quality molds can be expensive but often lead to better production efficiency.

However, even with careful planning, mistakes can happen. Sometimes molds may not perform as expected. This could lead to production delays or increased costs. It is essential to reflect on these challenges and learn from them. Engaging with experienced professionals can also provide valuable insights. The selection process is not just about specifications; it’s about finding balance and making informed choices.

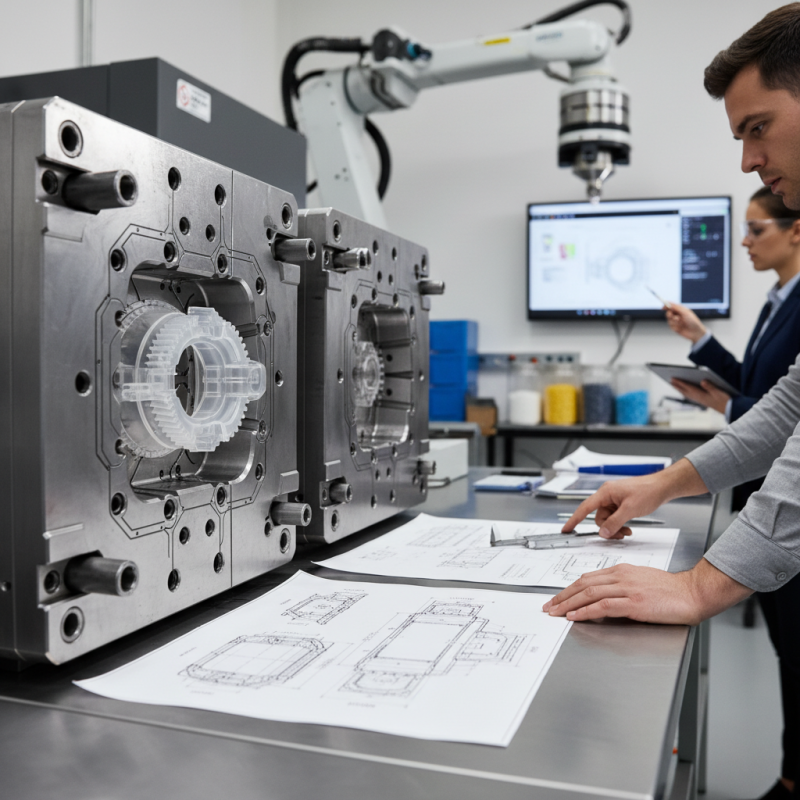

Plastic injection molding is a crucial process in modern manufacturing. It involves injecting molten plastic into a mold to create various products. The quality of the final product heavily depends on the mold design and material selection. According to a report by MarketsandMarkets, the global injection molding market is expected to reach $300 billion by 2025. This highlights the immense demand and importance of understanding this process.

When choosing a mold, factors like the mold's lifespan, type of plastic, and manufacturing volume are vital. Molds can vary significantly in cost and complexity. For instance, simpler molds may be cheaper but can limit production flexibility. In contrast, complex molds offer precision but require more significant investment. A study indicated that over 50% of production issues stem from poor mold design. This emphasizes the need for careful planning and analysis.

Moreover, the sustainability factor is becoming more crucial. Companies are looking for eco-friendly materials and processes. However, finding a balance between cost and sustainability can be challenging. While some manufacturers aim for low-cost solutions, sacrificing quality often leads to higher long-term costs. Addressing these challenges requires a comprehensive understanding of injection molding fundamentals.

Choosing the right plastic injection mold is crucial for project success. The first step is to identify your project requirements. Understand the part design, dimensions, and material specifications. This will set a clear foundation for your molding process. Consider the complexity of the design as well. Complex shapes may need more advanced molds, which can increase costs.

Tips: Determine the materials you will use. Different plastics require different molding techniques. Make sure your chosen mold can handle the material type efficiently.

Next, consider the production volume. Are you looking at small batches or high-volume production? This impacts the mold choice significantly. For high-volume needs, investing in a durable mold pays off. On the other hand, for lower volumes, simpler molds can suffice, but quality may suffer.

Tips: Always factor in future scalability. If your project grows, can your mold handle increased production? This foresight can save time and money in the long run. Don't forget about lead times as well. Delays in mold production can impact your project timeline, so plan accordingly.

When selecting a material for your injection mold, there are multiple factors to consider. Ideally, the material should match the final product's specifications. Common choices include steel and aluminum. Steel molds are durable and ideal for high-volume production. However, they are also more expensive and take longer to manufacture. Aluminum molds, in contrast, are faster and cheaper to produce. Yet, they may wear out quicker with extensive use.

It's essential to think about the complexity of your design. Some materials are better suited for intricate shapes. Consider the cooling efficiency as well. The choice of material can affect cooling times. Slower cooling can lead to defects. It's crucial to weigh these aspects carefully. Sometimes, a compromise must be made between speed and quality. Evaluation of your project's specific needs can help guide this decision.

Keep in mind that experimenting with different materials can yield unexpected results. Do not shy away from trial and error. Each choice made should be documented and assessed. This reflection can lead to better outcomes in future projects. Choosing the right material isn’t just a technical decision; it can define the success of your project. Take the time to understand the implications of each material choice.

When selecting a plastic injection mold, assessing design features is crucial for optimal performance. Key factors include material type, cooling methods, and mold geometry. Research shows that improper cooling can increase cycle times by 40%, affecting efficiency and cost. A well-designed cooling system can reduce these times significantly, enhancing productivity.

Mold geometry also plays a vital role. Complex geometries may require additional engineering considerations. The right draft angle can facilitate part ejection and minimize defects. Data indicates that a 2-degree draft angle can reduce ejection force by up to 20%. However, intricate designs can lead to higher production costs and extended lead times. A balance is necessary to meet performance and budget constraints.

Moreover, it's essential to consider how variations in the mold's design can impact the final product. Small changes in tolerances or surface finish can lead to significant issues. Reports suggest that 30% of injection molded parts fail quality inspections. Regularly reviewing design choices helps in minimizing these failures. Investing time upfront can save costlier redesigns later.

Choosing a reliable manufacturer for injection molds is crucial. Quality molds enhance production efficiency. In a recent industry report, 70% of firms highlighted cost as a major factor, but overlooked quality could lead to higher long-term expenses.

When evaluating manufacturers, examine their experience and expertise. A manufacturer with over a decade of experience often ensures better craftsmanship. Check their portfolio. A diverse range of successful projects is a positive indicator. Additionally, ask for client references. Genuine feedback can reveal potential flaws in the manufacturer's processes.

Communication is another key aspect. Manufacturers who respond promptly to inquiries demonstrate professionalism. In a survey, 65% of companies noted that poor communication delayed project timelines. Don't rush this decision. Investing time in choosing the right partner often yields better results in the long run. Aim for transparency in pricing and terms. Transparency can prevent future misunderstandings and regrets.

| Criteria | Details |

|---|---|

| Material Type | Choose based on the end product requirements (e.g., ABS, PC, Nylon) |

| Mold Complexity | Consider the number of cavities and intricate designs |

| Production Volume | Determine the estimated production quantity to select mold durability |

| Lead Time | Evaluate the manufacturer's ability to meet your project schedule |

| Cost | Compare quotes but assess value in terms of quality and service |

| Manufacturer Capabilities | Assess the technological capabilities and previous projects |

| Customer Support | Verify responsiveness and willingness to assist during production |

| Quality Assurance | Check for certifications and quality control processes |