SUNDI TOOLS

- Copyright © Wuxi Sundi Precision Tools Co.,LTD All rights reserved.

- Site Map

Choosing the right Stainless Hexagon Bar for your project can significantly affect its performance and durability. According to a recent report by the International Stainless Steel Forum, the demand for stainless steel products is projected to grow by 3% annually over the next five years. This indicates a strengthening market for materials like Stainless Hexagon Bars used in various applications, from automotive components to construction.

Industry expert Dr. Emily Carter states, “Selecting the right grade of Stainless Hexagon Bar can make or break your project’s success.” Understanding the specific requirements of your application is crucial. Factors such as corrosion resistance, tensile strength, and machining capabilities must be considered. A common oversight is neglecting the material's specifications, leading to project delays and increased costs.

Furthermore, it is essential to reflect on the common pitfalls. Choosing a cheaper grade may seem appealing, but this can result in inferior performance. Clients often underestimate the importance of these distinctions. Thus, being mindful in this decision-making process is key to achieving the desired outcomes in any project involving Stainless Hexagon Bars.

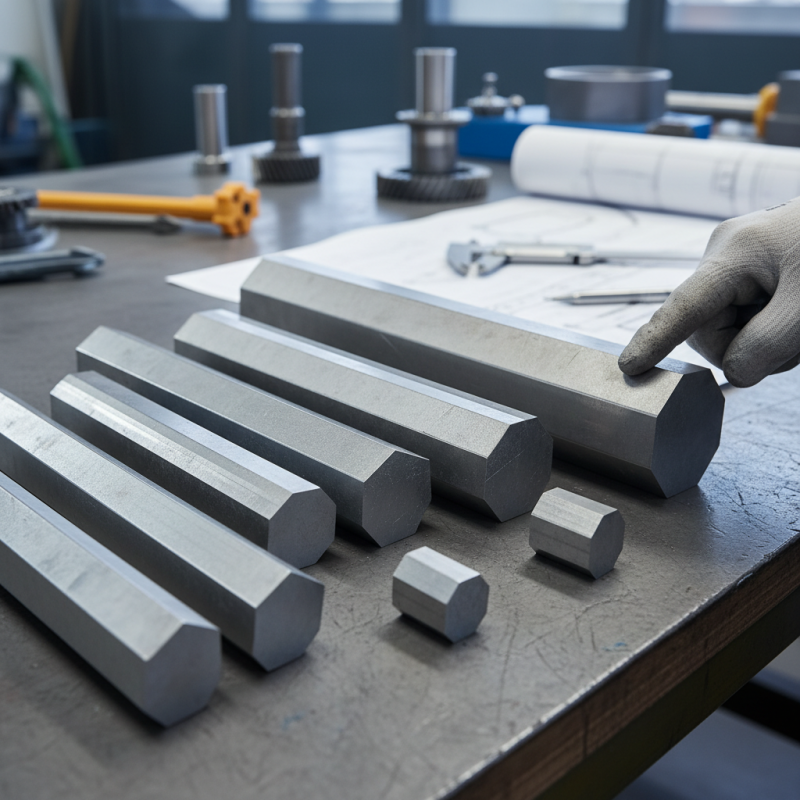

Stainless hexagon bars are versatile materials used in various industries. Their unique shape allows for easy gripping and secure fastening. These bars find applications in machinery, automotive, and construction projects. They offer excellent corrosion resistance, making them suitable for both indoor and outdoor use. The choice of material is crucial, as different grades of stainless steel can affect performance.

When selecting a hexagon bar, consider its size and thickness. A thicker bar may provide more strength, but it could also be heavier and harder to work with. More dimensions to ponder include the bar's finish and surface treatment. A polished surface can enhance durability but could also add to the cost. The specific application might mean you need to balance strength with weight considerations.

It's easy to overlook certain factors when choosing materials. A small flaw in selection might lead to significant issues later. Conducting thorough research can prevent these mistakes. Learning from past projects can guide future choices. Recognizing that no material is perfect is essential. Each decision carries weight, requiring careful thought and understanding of the intended use.

When choosing a stainless hexagon bar, understanding the grades of stainless steel is crucial. Different grades offer varying properties. For example, 304 stainless steel is highly resistant to corrosion and is suitable for many applications. In contrast, 316 stainless steel includes molybdenum, enhancing its resistance to corrosive environments. This makes it ideal for marine applications. Using the wrong grade could lead to premature failure.

A report from the International Stainless Steel Forum notes that the global consumption of stainless steel reached over 50 million tons in 2021. This reflects a growing reliance on stainless steel in various industries. However, only 10% of users conduct thorough evaluations before selecting a grade. Many overlook the specific environmental conditions that can influence material performance.

When sourcing hexagon bars, it’s wise to consider factors such as tensile strength and yield strength. For instance, 304 has a tensile strength of 520 MPa, while 316 can reach 580 MPa. Some projects may require higher strength, yet users often settle for 304 without consideration of actual project needs. This oversight can affect product durability in demanding conditions.

Choosing the right stainless hexagon bar is crucial for the success of your project. One essential factor to consider is the dimensions. Hexagon bars come in various sizes, including thickness and length. The right size will ensure proper fit and function in your application.

When selecting dimensions, think about the intended use. For instance, a bar used for structural support may require different dimensions than one for decorative elements. Check the design specifications carefully. If you choose an incorrect size, it can lead to costly mistakes. Sometimes, a small error in measurement can create significant issues.

Material standards also affect dimensions. Different grades of stainless steel have unique properties. These properties can influence the bar's performance. It's essential to match the material with the intended application. A miscalculation here might compromise strength or durability. Also, consider manufacturing tolerances, as variations can occur. Don't overlook these details; they are vital for project success.

| Dimension (mm) | Weight (kg/m) | Tensile Strength (MPa) | Applications |

|---|---|---|---|

| 10 | 1.08 | 520 | Fasteners |

| 12 | 1.56 | 520 | Machinery |

| 16 | 2.01 | 520 | Construction |

| 20 | 2.60 | 520 | Automotive |

| 25 | 3.92 | 520 | Aerospace |

When choosing a stainless hexagon bar, the surface finish plays a vital role. It affects not only the aesthetics but also the performance of the final product. A shiny, well-polished surface may look appealing initially, but it may not always be the best choice for all projects. Some applications require a more textured surface for better grip or adhesion, which can be overlooked easily.

Quality is also a significant aspect to consider. It’s important to check for imperfections such as scratches or pitting. These flaws can compromise the integrity of your project. Sometimes, a bar may seem perfect at first glance, but a closer inspection reveals hidden issues. This could lead to future problems during production or use.

Evaluating the quality of a hexagon bar may require patience, yet it is essential for successful outcomes. Many overlook this step, only to regret it later. A thorough assessment can save time and resources in the long run.

Choosing the right suppliers for stainless hexagon bars can significantly impact your project. Start by researching local suppliers. This can save on shipping costs and reduce lead times. Reach out to multiple vendors. Request quotes and compare prices carefully. Don’t forget to ask about the quality of materials they offer. Sometimes, the cheapest option isn’t the best choice.

Managing costs effectively is crucial. Look for suppliers that offer bulk discounts. This can help lower your per-unit cost. However, consider the amount you really need. Over-purchasing can lead to waste. It’s essential to balance quality and budget. Additionally, factor in shipping fees and potential delays. A low price might become expensive if the delivery is late or the quality is subpar.

Reflect on your decisions regularly. Are you sticking to your budget? Have you assessed the supplier's reliability? Maintaining open communication with suppliers can make a difference. Clear expectations can lead to better results. Be prepared to adjust your strategy as needed. Each project teaches valuable lessons. Embrace them to improve future choices.