SUNDI TOOLS

- Copyright © Wuxi Sundi Precision Tools Co.,LTD All rights reserved.

- Site Map

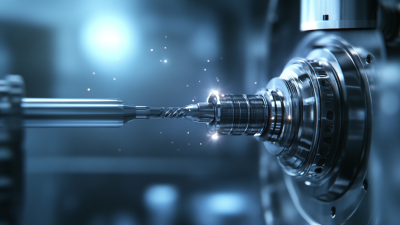

In the realm of precision engineering, the adoption of specialized tools is critical for achieving the highest levels of accuracy and efficiency. One such tool that has gained traction in various industries is the Gun Drill Tool, known for its ability to create deep and precise holes with minimal deviation. According to a report by MarketsandMarkets, the global market for precision drilling tools, including gun drills, is expected to reach USD 3.2 billion by 2026, driven by the increasing demand for high-performance machinery and components in sectors such as aerospace, automotive, and manufacturing. The Gun Drill Tool stands out due to its unique design and operational capability, allowing for optimal cooling and chip removal during the drilling process, which ultimately enhances tool life and reduces production costs. In this blog, we will explore seven essential benefits of using Gun Drill Tools, demonstrating their indispensable role in modern precision engineering solutions.

In the realm of precision engineering, the adoption of specialized tools is critical for achieving the highest levels of accuracy and efficiency. One such tool that has gained traction in various industries is the Gun Drill Tool, known for its ability to create deep and precise holes with minimal deviation. According to a report by MarketsandMarkets, the global market for precision drilling tools, including gun drills, is expected to reach USD 3.2 billion by 2026, driven by the increasing demand for high-performance machinery and components in sectors such as aerospace, automotive, and manufacturing. The Gun Drill Tool stands out due to its unique design and operational capability, allowing for optimal cooling and chip removal during the drilling process, which ultimately enhances tool life and reduces production costs. In this blog, we will explore seven essential benefits of using Gun Drill Tools, demonstrating their indispensable role in modern precision engineering solutions.

Gun drill tools are increasingly recognized for their critical role in achieving high tolerance levels in precision engineering. These tools utilize a unique design that allows for deep hole drilling while maintaining exceptional accuracy. According to a report by the International Journal of Advanced Manufacturing Technology, components produced with gun drilling show a tolerance level improvement of up to 50% compared to conventional drilling methods. This is particularly essential for industries such as aerospace and automotive, where precision is paramount for safety and performance.

Moreover, gun drill tools excel in producing holes with superior surface finishes, which is vital for reducing friction and wear in mechanical components. Extensive research highlights that the surface roughness achieved by gun drilling can be as low as Ra 0.1 micrometers, making it a preferred choice for high-performance applications. A study from the Society of Manufacturing Engineers indicates that utilizing gun drilling techniques can enhance the lifespan of components by up to 30%, underscoring the tangible benefits of incorporating these advanced tools into manufacturing processes.

Gun drilling has revolutionized precision manufacturing, particularly in reducing cycle times, a critical factor in today’s fast-paced production environments. By utilizing this specialized drilling technique, manufacturers can achieve deeper holes with finer tolerances and minimal friction. The design of gun drills allows for effective chip removal and coolant delivery, which not only enhances the quality of the drilled hole but also significantly cuts down the time required for machining operations. This efficiency translates into faster turnaround times and improved throughput, allowing companies to meet production deadlines and respond to market demands more rapidly.

Moreover, the impact of gun drilling on cycle time reduction is particularly evident in industries that require high precision, such as aerospace and automotive manufacturing. These sectors often deal with complex geometries and strict tolerance requirements that traditional drilling methods struggle to meet. By adopting gun drilling tools, manufacturers can streamline their processes, reduce the number of passes required, and minimize the downtime associated with tool changes or adjustments. This proactive approach not only saves time but also optimizes resource utilization, making gun drilling an essential practice in modern precision engineering.

| Benefit | Description | Impact on Cycle Time |

|---|---|---|

| High Precision | Gun drilling provides exceptional accuracy with tight tolerances. | Reduces setup time and rework due to improved fit and function. |

| Increased Tool Life | Specialized materials and coatings prolong durability. | Decreases downtime for tool changes. |

| Reduced Cycle Time | Streamlined processes allow for quicker drilling. | Can cut drilling time by up to 50%. |

| Chip Removal | Efficient removal of chips reduces chip related defects. | Minimizes interruptions during the drilling process. |

| Versatility | Suitable for various materials including hard metals. | Flexibility in manufacturing processes improves efficiency. |

| Cost-Effectiveness | Lower costs per part due to reduced cycle times. | Enhances overall productivity leading to better pricing. |

| Improved Surface Finish | Results in a smoother finish, reducing post-processing needs. | Leads to less time spent on finishing processes. |

Gun drilling and conventional drilling techniques differ significantly in their approach, precision, and applications. While conventional drilling methods are predominantly used for general hole-making tasks, gun drilling excels in creating deep, straight holes with high tolerances. This is chiefly due to its specialized tools that allow for precise coolant flow and consistent chip removal, ensuring a smoother and more accurate drilling process. Consequently, industries requiring stringent specifications, such as aerospace and automotive sectors, often prefer gun drilling over traditional methods.

When considering which technique to use, it's crucial to assess specific project requirements. For instance, if you're working with hard materials or need deep holes with enhanced accuracy, opting for gun drilling tools can save time and resources in the long run. Tip: Always evaluate the feed rate and speed settings based on your material type to achieve optimal results. Additionally, maintaining equipment and selecting the right drill bit for your specific application can enhance the efficiency of either drilling method. By understanding these differences, engineers can make informed decisions that lead to improved productivity and quality in their projects.

Gun drill tools are increasingly recognized for their cost-effectiveness in long-term precision engineering projects. These specialized drilling tools excel at creating deep, straight holes with minimal deviation, making them ideal for applications in various industries, including aerospace and automotive. By reducing the need for secondary operations, gun drills help streamline production processes, saving both time and money over the project’s lifespan.

Investing in gun drill tools may have higher initial costs compared to conventional drilling methods, but the long-term savings are significant. The enhanced efficiency and precision lead to reduced material waste and lower labor costs, as fewer man-hours are required to achieve the desired outcomes. Additionally, the durability and longevity of gun drill tools mean fewer replacements and repairs, resulting in better budget management for precision projects. As businesses look to optimize their operations, gun drills offer a financially sound solution that maximizes productivity while maintaining the highest standards of quality.

Gun drilling is a specialized technique that plays a crucial role in precision engineering, particularly in enhancing material efficiency and reducing waste. By using a long, thin drill bit, gun drilling allows for the creation of deep, accurate holes with minimal material loss. This approach is essential for industries where precision is paramount, such as aerospace and automotive manufacturing. As companies strive for sustainability, gun drilling offers a solution by maximizing the use of raw materials and minimizing scrap.

To further enhance the benefits of gun drilling, manufacturers should consider the following tips: First, ensure that the drill bit is made from high-quality materials, as this will increase durability and lead to smoother operations. Second, regularly maintain and sharpen the drill bits to maintain precision and efficiency. Third, leverage advanced drilling technologies, such as computer numerical control (CNC), to improve accuracy and control over the drilling process.

By focusing on these strategies, companies can fully capitalize on the advantages of gun drilling, paving the way for greater efficiency and sustainability in their manufacturing processes. This not only contributes to reduced costs but also aligns with the growing demand for eco-friendly practices in the industry.