SUNDI TOOLS

- Copyright © Wuxi Sundi Precision Tools Co.,LTD All rights reserved.

- Site Map

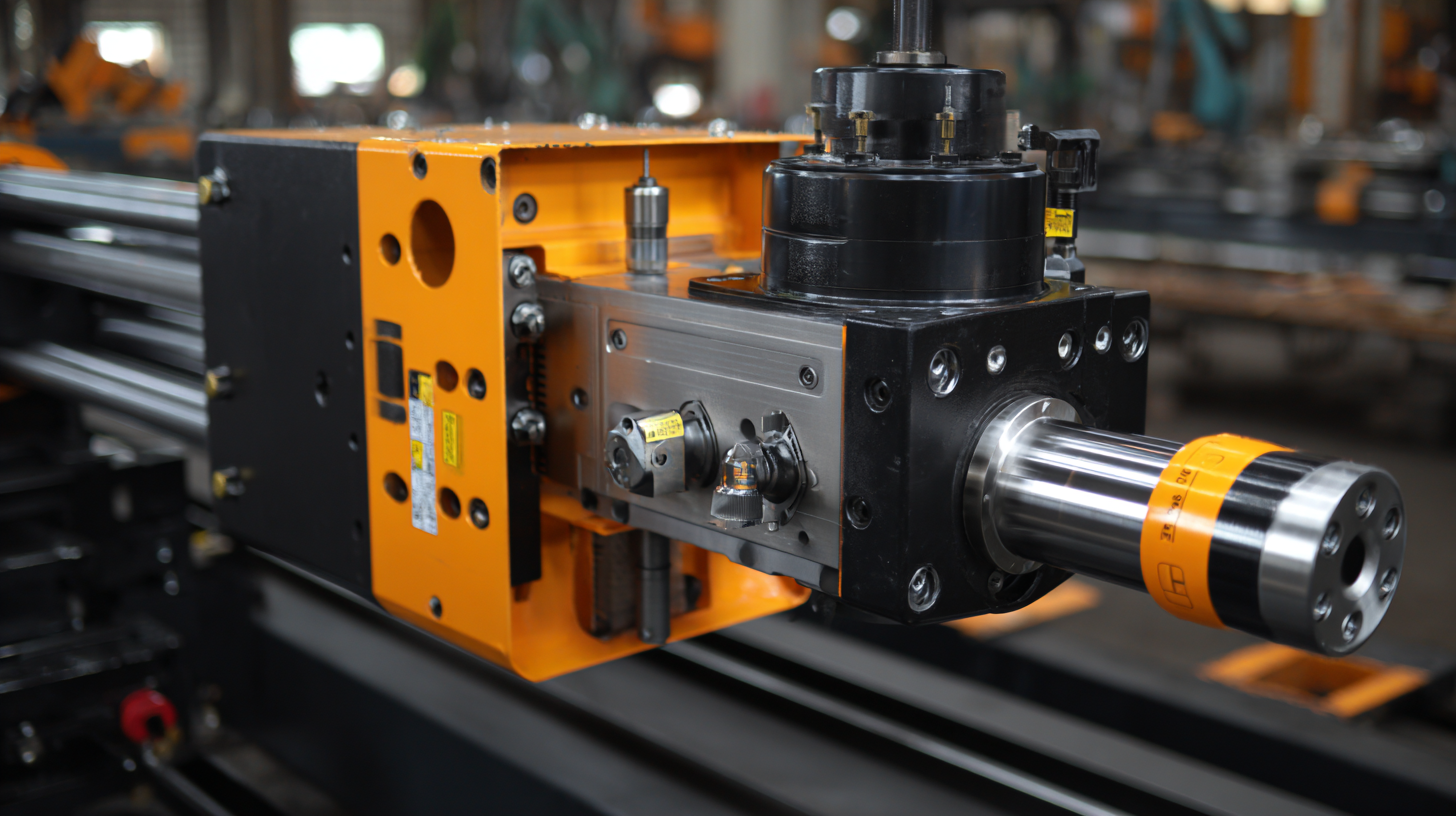

In today's competitive manufacturing landscape, the need for high-quality tools is paramount, especially when it comes to the reliable operation of a Hole Drilling Machine. As industries around the globe increasingly rely on precision machinery for effective production processes, understanding the production standards that govern these machines is crucial. Chinese manufacturers have gained a reputation for delivering excellence, thanks to their commitment to consistent quality and innovation. This blog will delve into the various industry production standards that ensure you get the best Hole Drilling Machine, highlighting how adherence to these standards not only improves performance but also boosts safety and efficiency. Join us as we explore the intricacies of these standards and the factors that contribute to the trusted reputation of Chinese-made machinery in the global market.

When it comes to selecting the best hole drilling machine, it’s crucial to understand the key factors influencing your decision. The global hole drilling machine market is projected to exceed $28.6 billion by 2024, with a compound annual growth rate (CAGR) of 4.9% anticipated between 2025 and 2034. This growth is largely driven by advancements in industrial automation and smart manufacturing technologies, which demand more efficient and reliable drilling solutions.

When evaluating which hole drilling machine to purchase, consider the configuration type—whether manual or machine-based—as this affects operational efficiency and suitability for specific projects. Additionally, product types such as drilling tools, milling tools, and turning tools each have distinct applications and performance characteristics that can influence your choice. Understanding the coatings—coated versus non-coated—will also play a vital role in durability and performance in varying materials, ensuring the machine meets the demands of user applications across diverse industries like automotive and construction.

When evaluating drilling equipment, understanding industry production standards is crucial. These standards ensure that machines meet the required safety, efficiency, and performance benchmarks. For instance, the International Organization for Standardization (ISO) has established guidelines that outline the minimum efficacy levels for various drilling operations. According to a report by the American National Standards Institute (ANSI), adhering to these standards can improve operational reliability by up to 30%. This points to a significant correlation between compliance with industry standards and the overall productivity of drilling tasks.

Tip: Always check if the drilling machine you intend to purchase is compliant with ISO or ANSI standards; this can serve as a quick verification of its quality.

Furthermore, industry specifics such as drilling depth, soil composition, and project duration greatly influence which standards are applicable. For instance, the Society of Petroleum Engineers (SPE) highlights that offshore drilling rigs must meet stricter environmental and safety regulations than land-based machinery, given the high-risk factors involved. Recognizing these nuances will guide operators in selecting the right equipment tailored to these demanding environments.

Tip: Consider engaging with vendors who offer equipment that exceeds the industry standards; this may provide an edge in highly competitive drilling projects.

By prioritizing machines that align with recognized production standards, operators can enhance both safety and effectiveness, ultimately leading to more successful drilling outcomes.

When it comes to selecting the best hole drilling machine, a comparative analysis of the top options available on the market is crucial. According to a recent report by Global Market Insights, the hole drilling equipment sector is projected to reach a valuation of over $14 billion by 2025, driven by advancements in technology and increasing demand across various industries, including construction and manufacturing. This growing market presents a myriad of choices, necessitating a thorough evaluation of performance, precision, and durability.

Leading brands like Bosch, Makita, and DeWalt consistently rank at the top for their innovative features and reliability. For instance, Bosch’s GBH18V-26B22 boasts an impressive impact energy of 2.1 Joules, making it ideal for tough materials. Additionally, its lightweight design enhances maneuverability, essential for extended use in diverse environments. Meanwhile, DeWalt's DCD996P2, equipped with a brushless motor, offers up to 82% more power for demanding applications. Such comparative data highlights the importance of technical specifications in guiding purchasing decisions, ensuring that consumers invest in machines that not only meet their immediate needs but also stand the test of time.

| Model | Power (HP) | Max Drill Depth (inches) | Weight (lbs) | Price ($) | Warranty (Years) |

|---|---|---|---|---|---|

| Model A | 2.5 | 12 | 45 | 2499 | 3 |

| Model B | 3.0 | 10 | 50 | 2899 | 2 |

| Model C | 1.5 | 8 | 40 | 1999 | 5 |

| Model D | 4.0 | 15 | 60 | 3499 | 3 |

| Model E | 2.0 | 7 | 35 | 1599 | 4 |

Maintaining drilling machines effectively is crucial for maximizing their lifespan and ensuring optimal performance. Regular inspections are a fundamental practice in this maintenance routine. Operators should carefully check all vital components, including the drill bit, motor, and hydraulic systems, for signs of wear or damage. This proactive approach can help identify issues before they escalate, allowing for timely repairs that minimize downtime and costly replacements.

Another best practice involves adhering to the manufacturer’s maintenance schedule. Each drilling machine has specific requirements for lubrication, filter changes, and other routine services. Following these guidelines not only enhances the machine's efficiency but also assures compliance with industry standards. Additionally, operators should invest in quality accessories and replacement parts to ensure compatibility and performance, as using subpar components can lead to mechanical failures and unsafe operating conditions. By prioritizing maintenance and following best practices, users can significantly enhance the durability and reliability of their drilling machines.

When it comes to hole drilling operations, understanding safety regulations and compliance is paramount. The drilling industry is governed by strict standards designed to protect workers and minimize risks associated with machinery and environmental factors. Compliance with regulations such as OSHA guidelines ensures that operators are trained, equipped, and prepared to handle potentially hazardous situations. This includes implementing proper safety protocols and routine inspections of drilling equipment to prevent accidents and ensure smooth operations.

Furthermore, the choice of a hole drilling machine plays a critical role in meeting these safety standards. Modern machines are frequently equipped with advanced safety features, such as emergency shut-off switches, automatic locking systems, and noise-reduction technologies. By investing in state-of-the-art equipment, companies not only comply with industry regulations but also foster a safer work environment. Understanding these compliance requirements is essential for businesses aiming to achieve operational excellence while safeguarding their workforce, ultimately leading to successful and sustainable drilling operations.

This chart illustrates the compliance rates of different hole drilling machines with safety regulations across various operational standards. The data indicates the performance of machines based on their adherence to established safety measures.