SUNDI TOOLS

- Copyright © Wuxi Sundi Precision Tools Co.,LTD All rights reserved.

- Site Map

In the fast-evolving landscape of modern manufacturing, the role of precision tools cannot be overstated. Among these essential instruments, the Cutting Router Bit stands out for its versatility and efficiency. As industries continuously strive for innovations that enhance productivity and quality, the application of advanced cutting techniques has become crucial. Cutting Router Bits have not only revolutionized woodworking but have also penetrated various sectors, including aerospace, automotive, and electronics, by offering unparalleled precision, smoother finishes, and remarkable adaptability to different materials.

This blog will explore the innovative applications of Cutting Router Bits and how they are shaping the future of manufacturing processes. From customizing intricate designs to facilitating rapid prototyping, these specialized tools are setting new standards for efficiency and creativity in production. By examining recent advancements and real-world case studies, we aim to provide insights into how businesses are leveraging Cutting Router Bits to optimize their manufacturing workflows, ultimately leading to reduced costs and enhanced product quality. Join us as we delve into the transformative impact of Cutting Router Bits on modern manufacturing trends.

In recent years, the woodworking and manufacturing industries have seen significant advancements in router bit technology, leveraging emerging trends that enhance precision and efficiency. According to market forecasts, the woodworking router bits market is projected to experience substantial growth from 2025 to 2035, driven by the increasing demand for precision cutting tools that optimize performance. Innovative designs and materials, such as carbide and diamond coatings, are now being incorporated into router bits, allowing for sharper cuts and longer tool life, ultimately reducing waste and downtime in manufacturing processes.

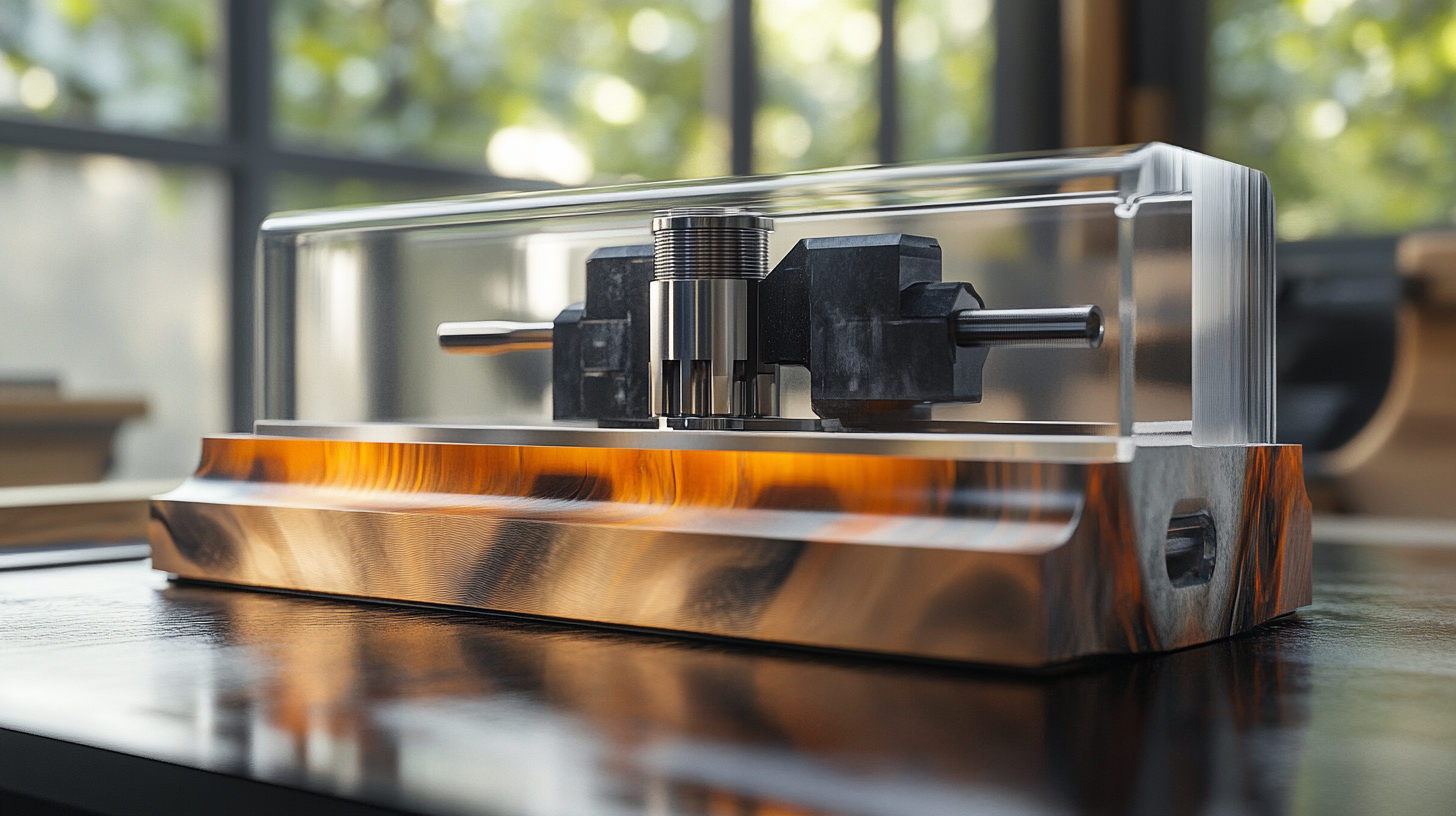

Moreover, the integration of AI technologies into CNC tools is reshaping how router bits are developed and utilized. Recent reports highlight the role of AI in enhancing productivity and precision, enabling manufacturers to execute complex designs with accuracy. The adoption of CNC routers equipped with smart technologies is transforming traditional woodworking processes, ensuring that manufacturers can meet the evolving demands of modern consumers looking for customized and high-quality products.

Additionally, the convergence of AI and advanced router bit design is leading to a new era of what can be termed “intelligent routing.” This not only allows for real-time adjustments during the cutting process but also provides data analytics that can help predict tool wear and automate maintenance schedules. As disruption continues across various industries, the impact of these innovations on router bit technology exemplifies the shift towards smarter, more efficient manufacturing solutions that prioritize both quality and sustainability.

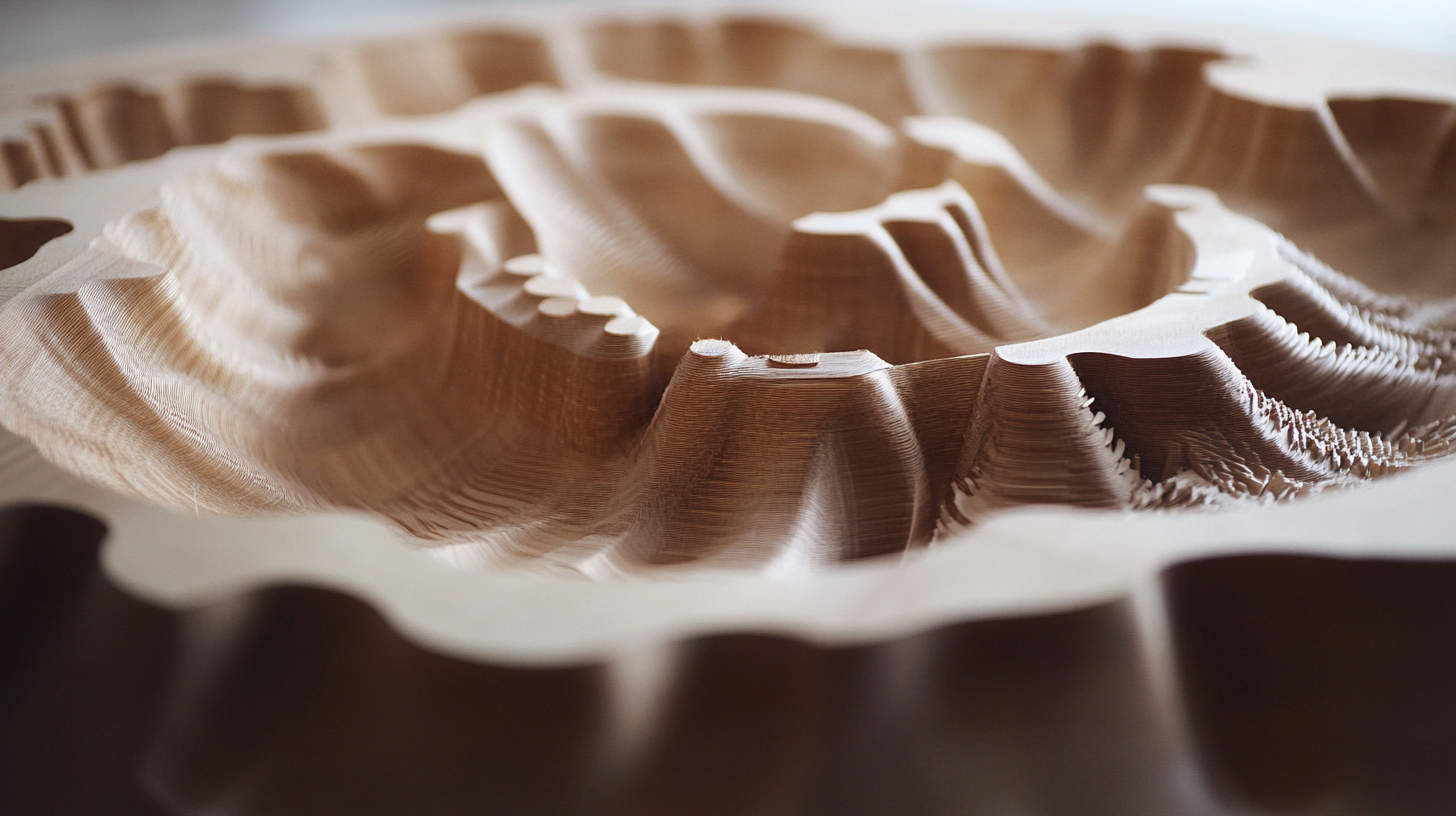

Cutting router bits have become essential tools in modern woodworking, transforming how artisans and manufacturers execute their craft. These innovative tools offer precision and versatility, allowing for intricate designs and seamless finishes that were previously unattainable. As the woodworking industry continues to evolve, the role of cutting router bits is becoming ever more central to enhancing productivity and creativity in furniture making and construction.

The woodworking CNC tools market is projected to grow significantly between 2025 and 2035, reflecting the rising demand for advanced machining solutions. As more manufacturers embrace automation and CNC technology, cutting router bits play a critical role in achieving high-quality results in less time. By enabling precise cuts and detailed carvings, these bits are revolutionizing the way woodworkers approach their projects, facilitating new design possibilities that cater to modern consumer preferences.

Moreover, the advancements in materials used for cutting router bits contribute to their effectiveness and lifespan. With innovations in carbide and diamond-tipped designs, these tools are not only more durable but also capable of producing smoother finishes. This technological evolution supports the increasing complexities of both residential and commercial woodworking projects, demonstrating that cutting router bits are indeed a cornerstone in the toolkit of today’s manufacturers and craftspeople.

This pie chart illustrates the various applications of cutting router bits in woodworking, showcasing their versatility in different areas of modern manufacturing.

Innovative router bit designs are playing a pivotal role in modern manufacturing, significantly transforming the efficiency and precision of material machining. Recent studies indicate that manufacturers utilizing advanced cutting router bits experience up to a 30% increase in productivity compared to traditional cutting tools. This boost is largely attributed to the enhanced geometries and materials used in the latest router bit designs, which optimize cutting speed and accuracy.

One notable innovation is the development of hybrid router bits that combine carbide and diamond coatings. According to a report from the International Journal of Advanced Manufacturing Technology, these hybrid bits can last up to three times longer than conventional carbide bits, leading to reduced tool replacement costs and less downtime in production lines. With less frequent changes needed, manufacturers can streamline their operations and focus on output.

Furthermore, the advent of computer-aided design (CAD) and computer numerical control (CNC) technology has elevated the capabilities of router bits. These technologies enable the creation of complex profiles that were previously infeasible, thus allowing for intricate designs in materials such as wood, plastics, and composites. A survey from the Manufacturing Innovation Network highlighted that 46% of companies reported improved design flexibility due to these advancements, facilitating the creation of products that meet evolving consumer demands. As such, the modernization of router bit design is not just about cutting efficiency; it's about expanding the horizons of what's possible in manufacturing.

This bar chart illustrates the efficiency improvements that innovative router bit designs bring to various manufacturing processes. The data reflects the percentage increase in production efficiency across different applications.

In recent years, the applications of cutting router bits have transcended traditional woodworking, finding remarkable relevance across various industries. From aerospace to electronics, these precision tools are being utilized to enhance productivity and product quality. A report from Grand View Research indicates that the global woodworking tools market is projected to reach $9.6 billion by 2025, highlighting the growing demand for innovative tooling solutions beyond just wood.

In the aerospace sector, router bits are critical in shaping lightweight composite materials, which are essential for improving fuel efficiency and lowering emissions. According to a study published by MarketsandMarkets, the aerospace composite market is expected to grow from $27.57 billion in 2020 to $67.50 billion by 2026, emphasizing the need for specialized cutting tools that can handle these advanced materials. Router bits developed specifically for composite machining can significantly reduce cycle times and improve surface finishes, which is vital for meeting stringent industry regulations.

The electronics industry is also leveraging cutting router bits for micro-machining applications, essential for producing intricate circuit boards and components. As reported by Mordor Intelligence, the global market for micro-machining is anticipated to grow at a compound annual growth rate (CAGR) of 7.5% between 2021 and 2026. By employing high-precision router bits, manufacturers can achieve the extreme tolerances required for modern electronics, contributing to the miniaturization trends seen in consumer gadgets today.

These examples underscore the versatility and critical importance of cutting router bits across a variety of fields, showcasing their role in driving innovation and efficiency in modern manufacturing processes.

In the quest for sustainability within the manufacturing industry, eco-friendly router bit solutions have emerged as a pivotal innovation. As highlighted by recent trends, companies like Novalk USA are leading the charge by introducing advanced coatings that not only enhance performance but also cater to the growing demand for environmentally conscious products. These innovative coatings are crafted to maximize durability while minimizing ecological impact, reinforcing the idea that manufacturing processes can be both efficient and sustainable.

Moreover, the woodworking sector is witnessing a significant transformation with the incorporation of smart technologies designed for energy and environmental sustainability. Emerging tools and methodologies are streamlining operations, promoting the use of renewable resources, and optimizing the cutting performance of router bits. This shift not only improves precision in manufacturing but also contributes to a broader eco-friendly initiative, enabling companies to reduce waste and conserve energy effectively.

As we move forward, the evolution of router bit technology alongside sustainable practices represents a critical pathway for the future of manufacturing. By prioritizing environmental considerations, industries can ensure that their operations align with global sustainability goals while still delivering high-quality, precise products. The integration of green solutions in manufacturing signifies a promising step toward a more responsible and eco-conscious industrial landscape.