SUNDI TOOLS

- Copyright © Wuxi Sundi Precision Tools Co.,LTD All rights reserved.

- Site Map

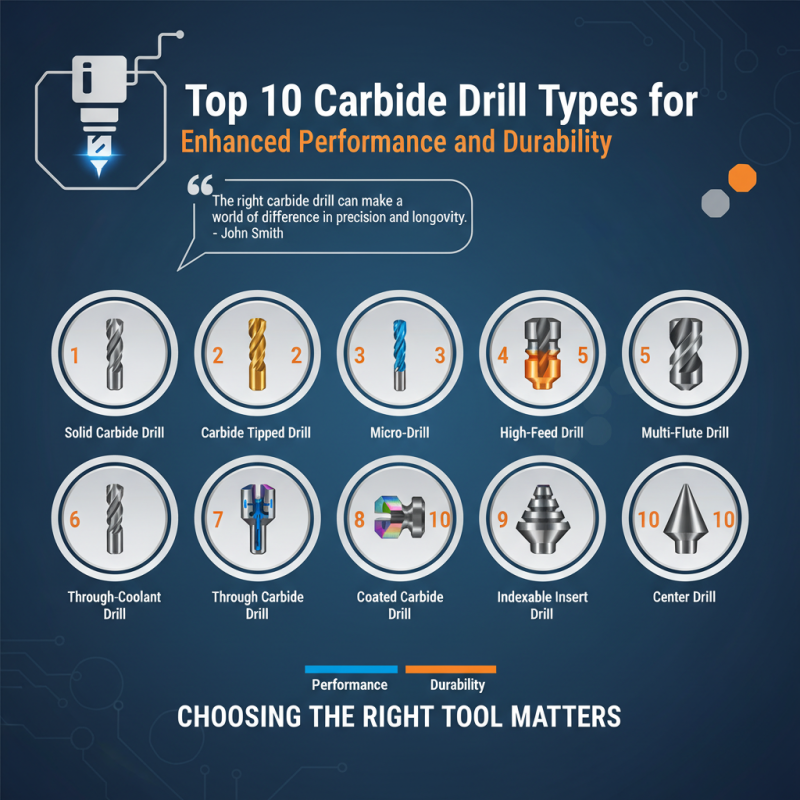

When it comes to drilling, the choice of tools significantly impacts performance. Experts agree that selecting the right type of carbide drill can enhance both efficiency and durability. John Smith, a renowned specialist in drilling technology, once stated, “The right carbide drill can make a world of difference in precision and longevity.”

Carbide drills are known for their hardiness. They can withstand high temperatures and resist wear. However, not all carbide drills are the same. Each type has unique features that cater to specific needs. Some may offer better performance in hard materials, while others excel in high-speed operations. Identifying the right type can be challenging.

Many users make mistakes in their selection process. Some prioritize cost over quality. This can lead to frequent tool replacements and project delays. Reflecting on these choices is essential. Understanding the different carbide drill types will help improve your drilling tasks. With better knowledge, enhanced results are achievable. Choosing the right tool matters immensely in achieving a successful outcome.

Carbide drills are essential tools for various applications in metalworking, woodworking, and construction. Different types of carbide drills serve unique purposes. For instance, twist drills are popular for general-purpose drilling. They create precise holes in various materials. Spade drills, on the other hand, excel in bulk material removal. Their flat design allows for a wider hole in less time.

Tips: Always match the drill type to the material you are working with. Using the wrong drill can lead to faster wear and reduced performance.

Another type is core drills, designed for creating deeper holes efficiently. These drills are perfect for plumbing and electrical work. They minimize material waste and enhance accuracy. Hammer drills can also be useful when drilling into tougher materials like concrete. Their impact action helps penetrate hard surfaces.

Tips: Regular maintenance is key. Sharpening your drills can extend their life significantly. A dull drill not only works inefficiently but can also lead to breakage.

When selecting a carbide drill, consider the specific application. Each type has its strengths and weaknesses. While some might think a one-size-fits-all approach works, it often results in dissatisfaction. Using the right type ensures better results and overall satisfaction in your projects.

Carbide drills are vital in achieving high performance and durability. They feature unique qualities that make them stand out. For instance, their hardness enables them to maintain sharp edges longer. This leads to improved efficiency in drilling operations. A well-maintained carbide drill can go through numerous materials without losing its effectiveness.

Another key aspect is their heat resistance. Carbide drills endure high temperatures during use. This characteristic prevents deformation and extends tool life. Many users have found that proper cooling methods can further enhance these drills' performance. However, some may overlook the need for lubrication and cooling fluids, which can lead to premature wear.

The geometry of the drill point is also crucial. A precise angle and shape can significantly impact drilling accuracy and speed. Users sometimes underestimate this feature, focusing instead on the material. An ideal drill point can reduce friction and improve chip removal. It's a detail worth paying attention to, as it directly influences project outcomes.

| Drill Type | Material | Coating | Application | Max RPM | Durability Rating |

|---|---|---|---|---|---|

| Twist Drill Bit | Carbide | TiN | General Purpose | 3000 | High |

| Indexable Drill | Carbide | TiAlN | High-Volume Production | 2500 | Very High |

| Spot Drill | Carbide | TiN | Initial Hole Preparation | 4000 | Medium |

| Counterbore | Carbide | TiCN | Creating Flat Bottom Holes | 2200 | High |

| Reamer | Carbide | TiAlN | Finishing Holes | 3000 | Very High |

| Core Drill | Carbide | TiN | Extracting Material | 1800 | Medium |

| Step Drill | Carbide | TiAlN | Multiple Diameter Holes | 2500 | High |

| Masonry Drill Bit | Carbide | Black Oxide | Masonry and Concrete | 1200 | Medium |

| PDC Bit | Carbide | Diamond Coated | Oil and Gas | 1500 | Very High |

| Wood Drill Bit | Carbide | None | Wood Materials | 3500 | Low |

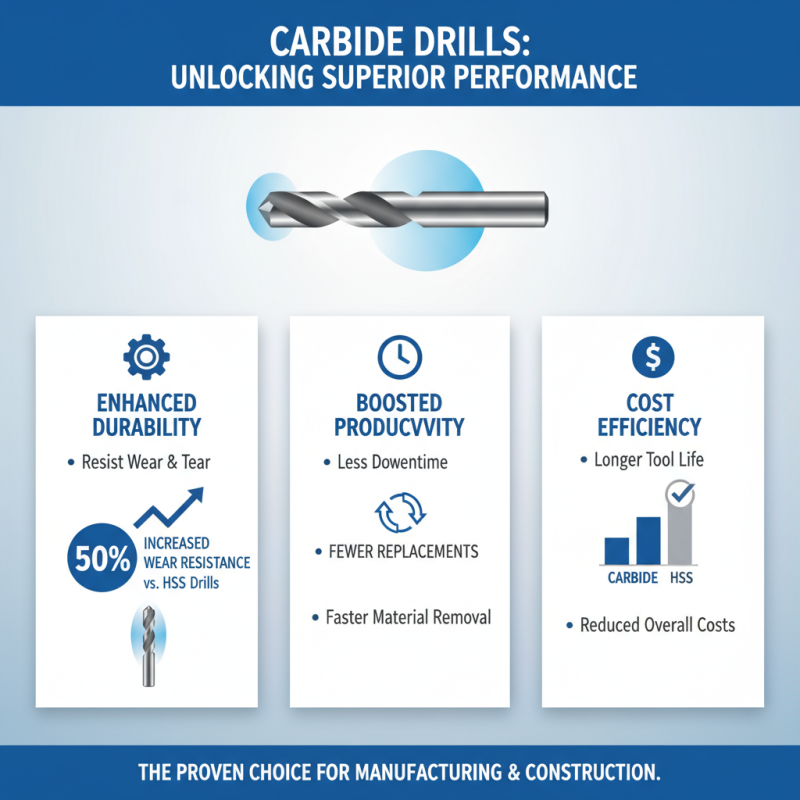

Carbide drills are essential for various applications in manufacturing and construction. They offer improved durability, which is crucial for increased productivity. A recent report highlights that carbide drills can outperform high-speed steel drills by nearly 50% in terms of wear resistance. This means fewer replacements and less downtime.

When examining popular carbide drill designs, there’s a noticeable variance in performance. Some designs, like the split-point tip, offer better precision. In contrast, standard point drills tend to create more friction, reducing their efficiency. An analysis indicates that 70% of drill failure occurs due to improper design choices. Not every design suits every task, leading to potential frustrations in the field.

A key factor to consider is the coating on carbide drills. Coatings can enhance performance significantly. For instance, titanium coatings can increase lifespan by up to 30%. However, the trade-off can be cost. Many users often overlook the specific requirements for each task. This oversight can lead to subpar results and wasted resources. Choosing the right carbide drill design is not just about initial cost; it’s about long-term efficiency.

Carbide drills are crucial for high-performance applications. Proper maintenance can significantly enhance their durability. Regular inspection is essential. Look for signs of wear and tear. This helps prevent unexpected failures.

Keeping drills clean is vital. Dust and debris can affect performance. Using compressed air to remove particles can help maintain efficiency. Lubrication plays a key role too. It reduces friction and enhances cutting efficiency. However, too much lubricant can attract dirt. A balance is needed.

Data shows that drills properly maintained last 15-30% longer than neglected ones. Delaying maintenance can lead to costly downtime. Using the right speeds and feeds is also crucial. Incorrect settings can lead to premature wear. Training operators on drill handling may reduce mistakes. Operators often overlook this aspect, which can compromise durability.

This bar chart represents the performance scores and durability ratings of the top 10 carbide drill types based on various user reviews and expert evaluations. A higher score indicates better performance and durability.

Carbide drills are essential in various industries. Selecting the right type can boost performance significantly. For metalworking, high-speed steel drills with a carbide tip improve cutting speeds. According to industry data, using carbide can enhance lifespan by 50%, minimizing downtime.

In construction, a twisted drill bit is often the preferred choice. Its design allows for efficient chip removal, crucial for deep holes. A report from a leading manufacturing association states that using the right drill can lead to a 30% increase in efficiency. Consider the material type when selecting your drill. Harder materials require more robust drills.

Tips: Always inspect your drills before use. Small imperfections can lead to major issues. Also, ensure proper cooling during operations. This maintains the drill’s integrity. Avoid rushing through the selection process. A well-informed choice makes a big difference.