SUNDI TOOLS

- Copyright © Wuxi Sundi Precision Tools Co.,LTD All rights reserved.

- Site Map

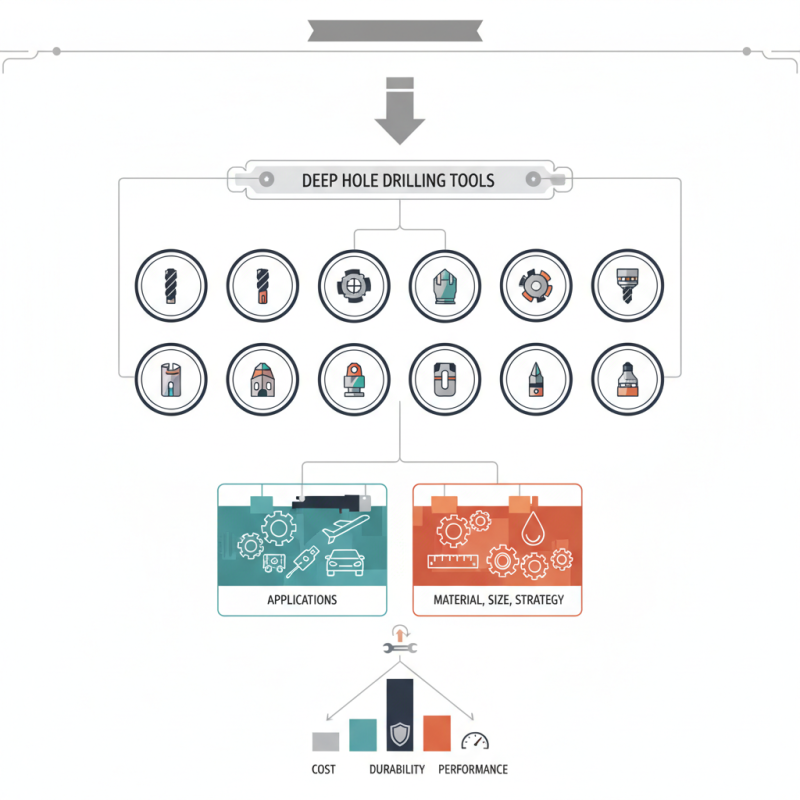

In the world of manufacturing and engineering, precision is key. Deep Hole Drilling Tools are essential for creating accurate and reliable holes in various materials. These tools accommodate a range of applications, from aerospace to automotive industries. Choosing the right tools can significantly impact efficiency and product quality.

Many options exist on the market today, but not all tools perform equally. Factors like material, size, and cutting strategy are crucial to consider. Investing time in understanding these elements can prevent costly mistakes. It is also important to note that even the best tools require regular maintenance. Neglecting this can lead to decreased performance and longevity.

As you explore the top 10 Deep Hole Drilling Tools, remember that every tool has its strengths and weaknesses. Reflecting on your specific needs will guide you in selecting the best options for your projects. Balancing cost, durability, and performance is vital in making an informed choice.

Deep hole drilling is a specialized technique used in various industries. It allows for precise drilling of depths that exceed conventional methods. This technique is essential in the production of components like hydraulic cylinders and aerospace parts. The ability to create deep and narrow holes means that manufacturers can achieve improved performance in their products. However, achieving success in deep hole drilling requires careful planning and the right tools.

There are different applications for deep hole drilling. You might find it in oil and gas exploration, where reaching deposits is crucial. Aerospace manufacturing also relies on this technique for lightweight structures. Yet, mistakes can be costly. Choosing the wrong tool or not considering coolant flow can lead to tool wear or even failure. This method demands attention to detail and innovation. Many professionals struggle with it, particularly when adapting to different materials or depths.

This field continues to evolve. New techniques and tools are being developed, but challenges remain. Many engineers encounter difficulties in balancing speed with precision. Understanding the nuances of deep hole drilling can greatly enhance productivity. As you explore this technique, remember that continuous learning is key to overcoming obstacles.

| Tool Name | Diameter Range (mm) | Max Depth (mm) | Material Compatibility | Typical Applications |

|---|---|---|---|---|

| Gun Drills | 1-30 | 5000 | Steel, Aluminum | Aerospace, Automotive |

| BTA Drills | 20-150 | 3000 | Cast Iron, Steel | Oil & Gas, Machinery |

| Pegasus Drills | 5-25 | 8000 | Alloys, Plastics | Electronics, Medical |

| Tapered Drills | 10-50 | 6000 | Aluminum, Bronze | Automotive, Aerospace |

| Solid Carbide Drills | 3-12 | 4000 | Hard Materials | Precision Parts |

| Step Drills | 4-20 | 5000 | Steel, Plastic | General Purpose |

| Twist Drills | 1-25 | 6000 | Wood, Metal | Construction, Repair |

| Screw Machine Drills | 2-20 | 2000 | Steel, Aluminum | Mass Production |

| Micro Drills | 0.1-5 | 1500 | Plastics, Metals | Medical, Electronics |

| Electro-Discharge Drills | 1-10 | 3000 | Conductive Materials | Tool Manufacturing |

When choosing deep hole drilling tools, consider their essential features carefully. Precision is critical. Look for tools that maintain tight tolerances. This ensures accurate drilling depths and diameters. Stability during operation is vital. Tools should resist bending and vibration for better results.

Tip: Always check the material of the drill bits. Harder materials can enhance durability. However, they may be more challenging to sharpen, requiring a balance.

Cooling systems in drilling tools greatly impact performance. Effective cooling prevents overheating and prolongs tool life. A tool that lacks proper cooling can lead to failures. Consider options that offer integrated cooling channels or systems.

Tip: Don't overlook the importance of the drill's weight. A heavier tool may be more stable but can be tiring to use over long periods. Explore lightweight alternatives that still offer strength.

Deep hole drilling can be complex. It's essential to reflect on the specific needs of your project. This allows you to select tools that align with your goals. Finding the right balance among various features may take time and experience.

Deep hole drilling requires specialized tools and expertise. Professionals turn to advanced equipment to achieve precision. According to industry reports, the global market for drilling tools is projected to grow significantly. By 2025, the demand for deep hole drilling tools is expected to increase by nearly 15%. This surge highlights the importance of efficient, reliable tools.

Among the top choices are specialized drill bits. These bits vary in design, tailored for specific applications. Carbide-tipped bits are particularly favored for their durability. They resist wear and maintain sharpness for longer periods. However, they can be costly and may require careful handling.

Coolant systems also play a crucial role. These systems prevent overheating during drilling. Effective cooling ensures extended tool life and enhanced performance. A study found that using proper cooling can increase the drill's lifespan by up to 40%. Despite advancements, operators often struggle with chip removal. Accumulated chips can lead to breakage and inaccuracies. Continuous refinement in tool design and operation remains a necessity in this field.

Deep hole drilling tools are essential in many industries. They come with various advantages and disadvantages. Understanding these can help make informed decisions.

Some tools offer precision. For instance, they're designed for deep drilling, with depths ranging from 10 to 200 times their diameter. This allows for intricate designs. However, their complex designs may require specific maintenance, which can be costly. Reports indicate that improper tool choice can lead to major downtime, averaging about 20% in productivity loss.

Tips: Always assess your project requirements. A thorough understanding of the material will guide your tool selection. Additionally, consider the potential for wear and tear. Some tools may lose effectiveness more quickly than expected.

Another consideration is cost-efficiency. Some tools may be cheaper initially but offer lower durability. They can require replacements sooner, raising overall project costs. Evaluating the total cost of ownership is crucial. A tool’s longevity can significantly affect budgeting.

Tips: Regular maintenance checks can prolong tool life. Schedule these assessments to avoid unexpected failures. Keeping track of usage will prevent unnecessary expenses.

This chart illustrates the performance ratings of the top 10 deep hole drilling tools, showcasing their effectiveness and efficiency based on various factors. Each tool is rated on a scale of 1 to 10, highlighting their comparative advantages in the field of deep hole drilling.

Deep hole drilling tools are vital in many industries. Proper maintenance can extend their lifespan significantly.

Start with regular cleaning. Dirt and chips can accumulate and lead to premature wear. Use a soft brush and compressed air to keep the tools clear. It’s simple but often overlooked.

Lubrication is key. Check the manufacturer's recommendations for the right type of oil. Too little lubrication can cause damage. Too much can attract more debris. It's a balancing act that requires attention.

Another common mistake is ignoring small damages. Even minor issues can escalate if not addressed. Regularly inspect cutting edges for wear. A small chip can lead to poor performance.

Storage conditions also play a role. Keep tools in a dry, cool place. Excessive moisture can cause rust. A dedicated toolbox can minimize exposure to contaminants.

Sketch a plan to organize and track your tools. An accessible system helps in monitoring wear.

Neglecting these simple maintenance practices can be costly in the long run.