SUNDI TOOLS

- Copyright © Wuxi Sundi Precision Tools Co.,LTD All rights reserved.

- Site Map

In the evolving landscape of manufacturing, precision is more critical than ever, with recent reports indicating that up to 80% of manufacturing defects can be traced back to inadequate tooling accuracy. Among the tools that significantly enhance manufacturing precision, the Step Reamer stands out as a game-changer. This versatile tool not only expands holes to precise diameters but also ensures smooth finishes and accurate depths, reducing instances of rework and scrap. According to a study by the Manufacturing Institute, the implementation of high-precision tools like Step Reamers can boost productivity by approximately 15%, while simultaneously lowering production costs. As industries strive to meet increasing demands for quality and efficiency, understanding the real-world applications and benefits of the best Step Reamer becomes essential for manufacturers aiming to unlock precision in their operations.

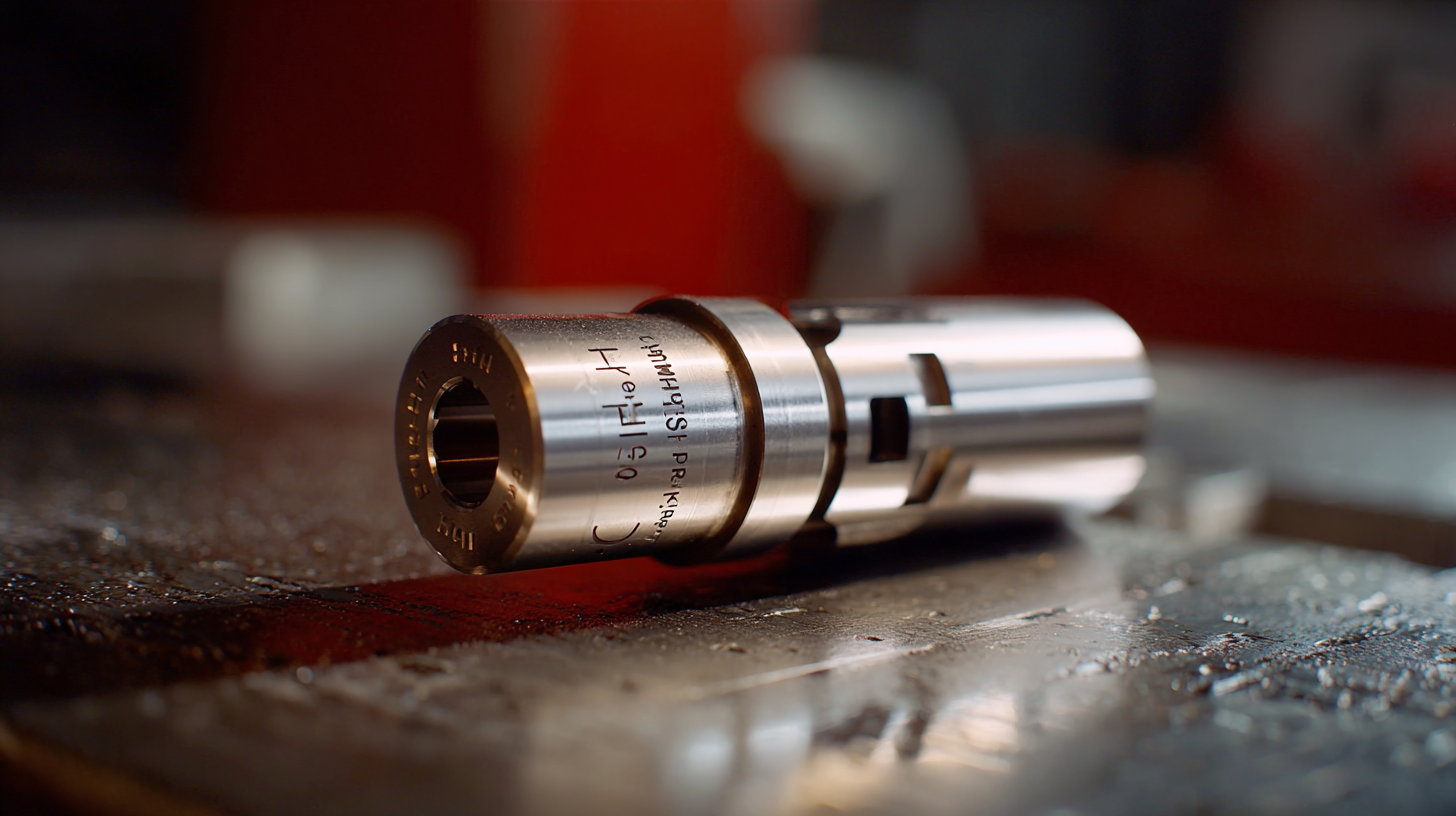

A step reamer

is a specialized cutting tool designed to create holes with varying diameters in a single pass. Unlike traditional reamers, which typically cut to a uniform diameter, step reamers feature multiple steps or flutes of different sizes. This unique design allows manufacturers to achieve precise hole dimensions without the need for multiple tools or machining operations. The versatility of step reamers makes them particularly valuable in industries where high precision and efficiency are paramount, such as aerospace and automotive manufacturing.

The operation of a step reamer is straightforward yet effective. As the tool rotates, the leading edge of the reamer enters the material and gradually cuts its way through, transitioning smoothly between the different diameters of the steps. This ensures that the final hole is not only accurate but also has a smooth finish, reducing the need for additional processing. By enabling quicker setups and reducing tool changeovers, step reamers significantly enhance productivity on the shop floor, making them an indispensable tool for manufacturers focused on efficiency and precision.

When it comes to optimizing machining processes in manufacturing, selecting the right type of step reamer can significantly enhance precision and efficiency. Step reamers come in various designs tailored for different applications, each offering unique advantages. For instance, standard step reamers are ideal for producing precision holes with multiple diameters, making them a go-to choice for general manufacturing needs. These tools are essential when a simple hole needs to be transformed into a multi-sized bore, allowing for the accommodation of various components and fasteners.

For applications requiring higher precision, precision ground step reamers are recommended. Made from high-quality materials, these reamers offer superior durability and accuracy, ideal for industries that demand exact specifications, such as aerospace and automotive manufacturing. Additionally, custom step reamers can be designed to cater to specific requirements, allowing manufacturers to achieve precise tolerances for unique components. Therefore, understanding the different types of step reamers available in the market is crucial for manufacturers looking to improve production quality and efficiency.

In precision engineering, the importance of product accuracy and quality cannot be overstated. Step reamers play a crucial role in this regard by allowing manufacturers to achieve precise hole dimensions in various materials. Unlike traditional reamers, step reamers are designed with multiple cutting diameters along their length, enabling the user to create a series of holes with different sizes in a single operation. This innovative approach not only enhances efficiency but also reduces the risk of error, ensuring that the final product meets stringent specifications.

The application of step reamers extends beyond mere hole enlargement; they also aid in improving the surface finish of machined parts. By providing a clean and uniform finish, step reamers contribute to the overall integrity and durability of components used in high-stakes industries such as aerospace, automotive, and medical manufacturing. The precision offered by step reamers not only streamlines the manufacturing process but also significantly boosts the quality of the end product, thereby enhancing customer satisfaction and trust in the brand. As manufacturers continue to seek ways to optimize their processes, step reamers emerge as indispensable tools in the quest for excellence in precision engineering.

| Application Area | Step Reamer Size (mm) | Material | Tolerance (mm) | Production Rate (units/hour) | Quality Improvement (%) |

|---|---|---|---|---|---|

| Aerospace Components | 6-12 | Titanium Alloy | ±0.02 | 50 | 15 |

| Automotive Parts | 8-14 | Carbon Steel | ±0.03 | 80 | 20 |

| Medical Devices | 4-10 | Stainless Steel | ±0.01 | 30 | 25 |

| Electronics | 2-8 | Aluminum Alloy | ±0.015 | 100 | 18 |

| Construction Equipment | 12-18 | High Carbon Steel | ±0.05 | 60 | 10 |

Step reamers play a crucial role in various manufacturing sectors, notably automotive and aerospace. In the automotive industry, precision in hole diameter and finish is essential for parts such as engine block assemblies and transmission components. According to a report from the Automotive Manufacturing Association, utilizing step reamers can enhance hole accuracy by up to 40%, significantly reducing the need for rework and thereby optimizing production efficiency.

In aerospace manufacturing, where tolerances are often measured in thousandths of an inch, the application of step reamers is indispensable. The Aerospace Industries Association notes that using high-quality step reamers can improve assembly alignment by 25%, contributing to the overall safety and performance of aircraft. The versatility of step reamers makes them ideal for creating precise holes across various materials, from aluminum alloys to composite materials used in modern aircraft.

In aerospace manufacturing, where tolerances are often measured in thousandths of an inch, the application of step reamers is indispensable. The Aerospace Industries Association notes that using high-quality step reamers can improve assembly alignment by 25%, contributing to the overall safety and performance of aircraft. The versatility of step reamers makes them ideal for creating precise holes across various materials, from aluminum alloys to composite materials used in modern aircraft.

Tip: When selecting a step reamer, consider the material you will be working with to ensure optimal performance. For example, carbide-tipped reamers are best for hardened steels, while high-speed steel is suitable for softer materials. Additionally, maintaining proper cutting speed and lubrication can significantly prolong the tool's life and improve the quality of your finished parts.

Step reamers are essential tools in manufacturing, renowned for their ability to create precisely sized holes with minimal deviation. To maintain their performance and extend their lifespan, it's crucial to adhere to best practices for maintenance. According to the latest industry report by the Manufacturing Institute, improperly maintained tools can lead to a 40% decrease in efficiency and significantly increase operational costs. Regularly cleaning step reamers to remove debris, along with periodic inspections for wear, can mitigate these issues and ensure consistent output quality.

Lubrication is another critical aspect of step reamer maintenance. The use of proper cutting fluids reduces friction, resulting in less heat generation and prolonging tool life. A study from the Society of Manufacturing Engineers indicates that tools subjected to adequate lubrication can last up to 30% longer than those that are not. Additionally, adjusting cutting speeds and feeds according to the material being machined can optimize performance, minimizing tool stress and wear. By implementing these maintenance strategies, manufacturers can enhance the reliability and efficiency of their step reamers, driving productivity and reducing downtime.