SUNDI TOOLS

- Copyright © Wuxi Sundi Precision Tools Co.,LTD All rights reserved.

- Site Map

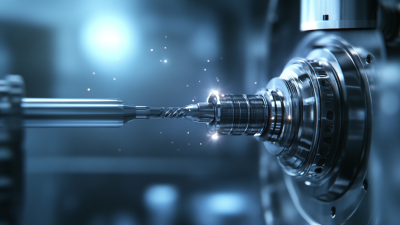

In the ever-evolving landscape of manufacturing and precision engineering, the use of specialized tools like Step Reamers has become increasingly vital for achieving optimal results. According to a recent report by Market Research Future, the global reaming tools market is projected to reach $2.1 billion by 2027, driven by the growing demand for high-precision components across various industries. Step Reamers, known for their unique design that allows for the enlargement of existing holes while maintaining a high degree of accuracy, play a crucial role in this trend. However, maximizing their effectiveness requires a deeper understanding of their operational intricacies.

This blog will delve into five essential tips that will enhance the use of Step Reamers, ensuring that manufacturers not only improve productivity but also elevate the quality of their final products.

Step reamers are specialized cutting tools designed to enlarge and shape holes in various materials, commonly used in metalworking and manufacturing processes. They come in different types, including straight flute, spiral flute, and parabolic flute reamers, each engineered for specific applications. According to a recent report by Grand View Research, the global cutting tools market, which includes reamers, is projected to reach $35 billion by 2025, driven by advancements in technology and increasing demand in various industries such as automotive and aerospace.

The application of step reamers can significantly enhance precision and efficiency in hole preparation and finishing operations. For instance, they are essential in creating specific diameter steps in a single pass, thus reducing machining time and improving overall productivity. Industrial surveys indicate that using optimized cutting tools can lead to a productivity increase of up to 30%. Furthermore, the ability of step reamers to maintain tighter tolerances compared to standard reamers makes them particularly valuable in high-precision applications, underlining the importance of selecting the appropriate type for specific projects.

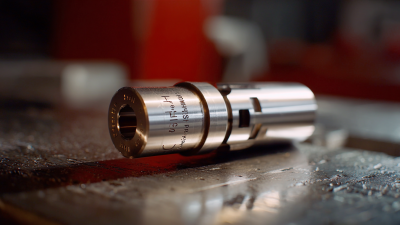

When selecting a step reamer for your project, several critical factors should guide your decision. Firstly, consider the material of the step reamer; high-speed steel (HSS) reamers are suitable for softer materials, while carbide-tipped reamers are more effective for harder materials, as indicated by industry reports showing that carbide tools can enhance tool life by up to 50% compared to HSS in certain applications. Always align the reamer’s capability with the specific requirements of your project to ensure optimal performance.

Another key factor is the size and step configuration of the reamer. According to recent studies, reamers with multiple steps can provide better adaptability across various hole sizes, reducing the need for multiple tool changes and improving operational efficiency by as much as 20%. Additionally, pay attention to the flute design, as it greatly influences chip removal and overall cutting performance; a well-designed flute allows for smoother operation and can significantly minimize the risk of tool binding, further enhancing productivity on-site.

| Tip | Description | Material Compatibility | Recommended Use |

|---|---|---|---|

| 1. Choose the Right Material | Consider the type of material you'll be working with to select a reamer that ensures optimal performance. | Steel, Aluminum | Reaming holes in soft metals. |

| 2. Understand the Step Size | Select a step reamer that matches the hole sizes needed for your project to avoid unnecessary adjustments. | Various materials | Achieving precise hole dimensions. |

| 3. Consider the Cutting Angle | The cutting angle can affect chip removal and overall cutting efficiency. | Hard metals | Deep reaming operations. |

| 4. Look for Coatings | Coatings can reduce friction and extend the life of the reamer. | All types | Improving durability and performance. |

| 5. Ensure Proper Tool Maintenance | Regular maintenance and cleaning of tools can prevent damage and maintain effectiveness. | N/A | General use. |

When it comes to achieving precision in machining, employing step reamers effectively is crucial for enhancing operational efficiency. According to a report from the Precision Machining Association, steps in reaming operations can reduce cycle time by up to 30% when the correct techniques are applied. One key technique is ensuring optimal cutting speeds and feeds. Based on extensive industry studies, using a cutting speed that is 75% of the material's recommended maximum can lead to a significant increase in tool lifespan and overall precision.

Additionally, proper lubrication is paramount in the step reaming process. The right cutting fluid decreases friction and aids in chip removal, facilitating better surface finishes. Research shows that using advanced synthetic lubricants can enhance tool life by up to 40%. Moreover, maintaining a consistent approach angle during the reaming process ensures a clean, precise finish while reducing the risk of tool deflection. Implementing these best practices not only contributes to the accuracy and efficiency of step reaming but also positions manufacturers to meet the stringent demands of modern precision engineering.

Proper maintenance of step reamers is crucial for ensuring their longevity and performance in various applications. One key aspect is regular cleaning, as accumulated debris can drastically affect the reamer's effectiveness. By keeping the cutting edges clear of material build-up, you allow the tool to operate at optimal levels, thus extending its life. It’s also essential to inspect the reamers regularly for wear and tear; identifying any damage early can prevent more serious issues down the line, ensuring that your tools remain in top condition for rigorous tasks.

Incorporating innovative solutions, such as a welding reamer, can further enhance the maintenance of your step reamers. Using a welding reamer can minimize spatter and debris that often accumulate during operations, leading to cleaner working conditions. This not only improves the quality of the welds but also protects other consumables from wear, thereby extending their lifespan. Adopting these maintenance tips will ensure your step reamers operate efficiently, providing consistent results while minimizing downtime caused by tool replacement or extensive repairs.

Understanding the frequency of maintenance and performance impact can help extend the life of step reamers. The chart below illustrates the average lifespan of step reamers based on maintenance frequency.

When using step reamers, operators may encounter several common issues that can hinder their machining process. One frequent problem is excessive tool wear, often due to incorrect feed rates and speeds. To mitigate this, it’s essential to match the cutting parameters to the material being worked on. Regularly checking and adjusting the tooling settings can help maintain optimal performance and prolong the life of your step reamers.

Another issue that practitioners face is improper chip removal, which can lead to clogging and reduced efficiency. To resolve this, ensuring adequate coolant flow and using the appropriate type of coolant can significantly enhance chip clearance. Additionally, selecting the right reamer geometry for specific applications can prevent build-up and improve machining accuracy. With these troubleshooting strategies in place, operators can achieve better results and make the most of their step reaming operations.